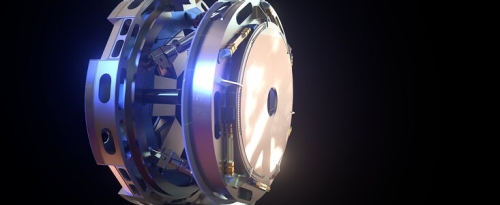

The largest adaptive mirror ever built, the M4 mirror for ESO’s upcoming Extremely Large Telescope (ELT), has reached an important milestone in its development: all six petal-shaped segments that make up the mirror are now completed. M4, the fourth mirror in the light path of the telescope, can change shape quickly and very precisely, and is a key part of the ELT’s adaptive optics system.

ELT M4 Adaptive Mirror Petals Completed

Light from cosmic objects is distorted by our planet’s atmosphere, producing blurred images. To correct for these distortions, the ELT will use advanced adaptive-optics hardware and software, some of which has been specially developed for the telescope. This includes powerful lasers that create artificial reference stars when there are no stars bright enough close to the object of interest to allow measurements of atmospheric distortions, and fast and accurate sensing cameras that measure these distortions. The measurements are then passed to extremely fast real-time computers that can calculate the necessary shape corrections to be applied to M4. In addition to the completion of the M4 petals, these systems have also all recently achieved key milestones.

With a diameter of 2.4 metres, M4 is the largest deformable mirror ever made and one of the most challenging and exciting components of the ELT. It is made up of six ultra-thin segments, the last two of which have now been finalised. The six petals of M4 are made from Zerodur©, a special glass-ceramic material manufactured by SCHOTT in Germany. The French company Safran Reosc began polishing the M4 petals in 2017, turning each 35 mm-thin sheet of Zerodur© into a flexible segment less than 2-mm thick. All petals were checked by ESO engineers before being sent to Italian company AdOptica, who received the final one just a few months ago.

During the final production stages AdOptica have applied a coating to the mirror’s back surface and put in place lateral supports to connect the petals to the M4 mechanical structure. In addition, the companies’ technicians have glued more than 5000 magnets onto the mirror’s back surface, which play a role in deforming the flexible segments of M4, making adjustments 1000 times per second to an accuracy of 50 nanometers — as small as the tiniest viruses. Now Safran Reosc is working to produce an identical set of petals, bringing the total number to 12. These will serve as spares and will be swapped out with the original six petals when they require recoating after a few years of use, minimising disruption to telescope observing time.

More information about this and other recently achieved ELT Adaptive Optics milestones can be found here.