Device Manager¶

The Device Manager provides the functionality for supervision and management of a configurable set of devices.

The Device Manager provides a library of devices implementing the communication with the respective device controllers in the PLC. Devices are created at the manager start-up by a device factory class. The main components of the Device Manager server are:

State Machine engine based on SCXML and implemented in RAD. It contains a set of action and activity classes.

A Device Factory class that creates the instances of all device classes at start-up and based on the server configuration.

A set of Device classes. Each device has two additional classes: one for the device configuration and the other one for the interface with the Local Control System (LCS).

A Facade class that manages the interface between the state machine engine and the device classes.

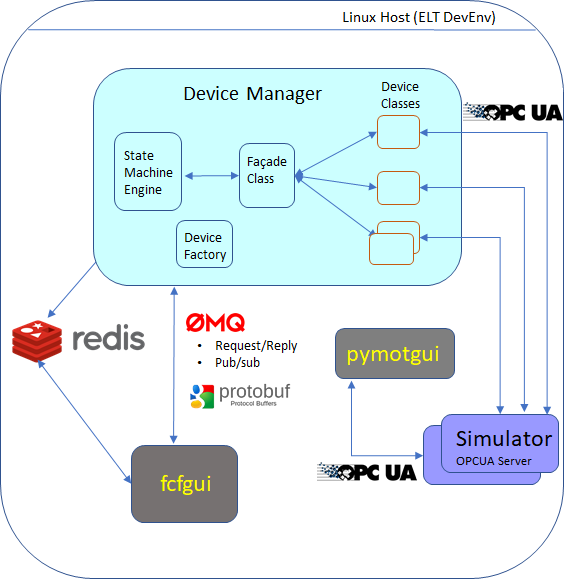

Device Manager Components without LCS.¶

Client applications, such as fcfGui, send commands to the Device Manager using the CII MAL library (request/reply). The fcfGui is subscribed to the device topic changes published by the Device Manager through CII MAL (pub/sub).

The Device Manager uses the Redis Database to store run-time information about itself and about the devices it controls. In absence of a Local Control System, device classes can connect to the Device Simulator via the OPC-UA protocol, see figure above.

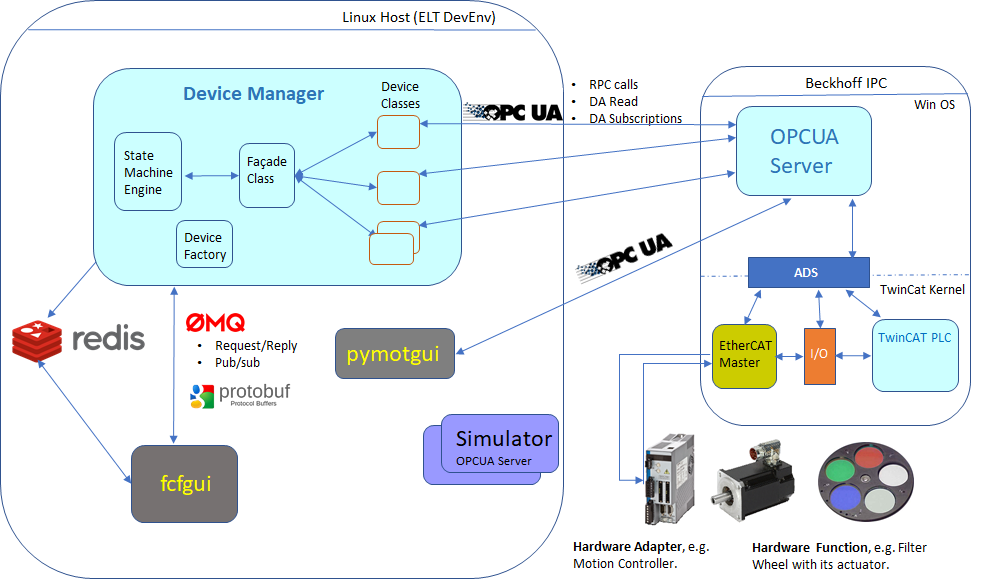

In normal operation, device classes connect to the OPC-UA server running under the Windows OS side of the Beckhoff IPC, e.g .CX2030. This communication is based on the execution of RPC calls (OPC-UA Method profile). Each Device Controller running in the TwinCAT PLC declares a number of methods defining the interface with the Device Manager. Additionally, the device classes subscribe to the status data produced by the device controllers. Each time the status changes, the device classes are notified and they updates the Redis DB and publish the corresponding changes via CII (pub/sub).

The PLC OPC-UA Server connects to the device controllers via the vendor specific protocol (ADS). The device controllers trigger the changes in the hardware via the TwinCAT I/O mapping.

Device Manager connecting to a Beckhoff IPC.¶

Supported Devices¶

Shutters¶

The Shutter device is a general purpose device for controlling a shutter hardware function. The device can control the shutter open/close.

Lamps¶

The Lamp device is a general purpose device for controlling a lamp hardware function. The device can switch a lamp on/off, control the intensity and handle warm-up and cool-down times when this is supported.

Motors¶

The Motor device is a general purpose device that controls different types of motors. It provides the following features:

Support three different axis types: Linear, Circular and Circular-Optimized. Circular-Optimized means that the motor will always take the shorter path to reach the target position.

Definition of named positions in user units or encoder values.

Arbitrary positioning given in user units or encoder values.

Positioning in absolute or relative units.

Support for configurable Initialization Sequence.

Support for SW limits.

Support for various timeouts.

Auto disabling when standing.

Support for brake handling.

Support for backlash compensation.

Sensors¶

The Sensor device is a device that groups instrument engineering variables for the purpose of monitoring and recording of the instrument status and its subsystems over time. It can be configured with a variable number of channels that are grouped logically. The Sensor device supports three different channel types: Digital input, Analog input and Integer input.

Derotators¶

The Derotator device is an aggregated motor device that continuously adapt its position according to the field or pupil rotation. It supports four different modes:

Stationary: Derotator moves to a target position based on the position angle and remains standstill after reaching the target.

Sky: The Derotator is continuously moving to compensate for field rotation.

Elevation: The Derotator is continuously moving to compensate for pupil rotation.

User: The Derotator is continuously moving according to a customized computation of the position defined by the user.

ADCs¶

The ADC device manages the position of two prisms with the aim of correcting for the atmospheric dispersion.

The device supports two modes:

Auto: The ADC is continuously positioning the two motors based on the telescope RA/DEC, the environmental parameters and the ADC configuration.

Off: The ADC moves to a target position and remains standstill after reaching the target.

Piezos¶

The ‘Piezo’ device manages the control of the output signals of a piezo hardware. It supports up to three axes. The device can be set in two modes:

Auto: The Piezo is correcting continuously the outputs based on the feedback signals.

- Pos: The Piezo set the output of the axes to a fixed value. In this mode, the Piezo can

be controlled in user positions (normally volts) or directly in bits.

Actuator¶

The Actuator device is a general purpose device for controlling actuators through a switch signal (on/off). The most common use of astuators is for power control.

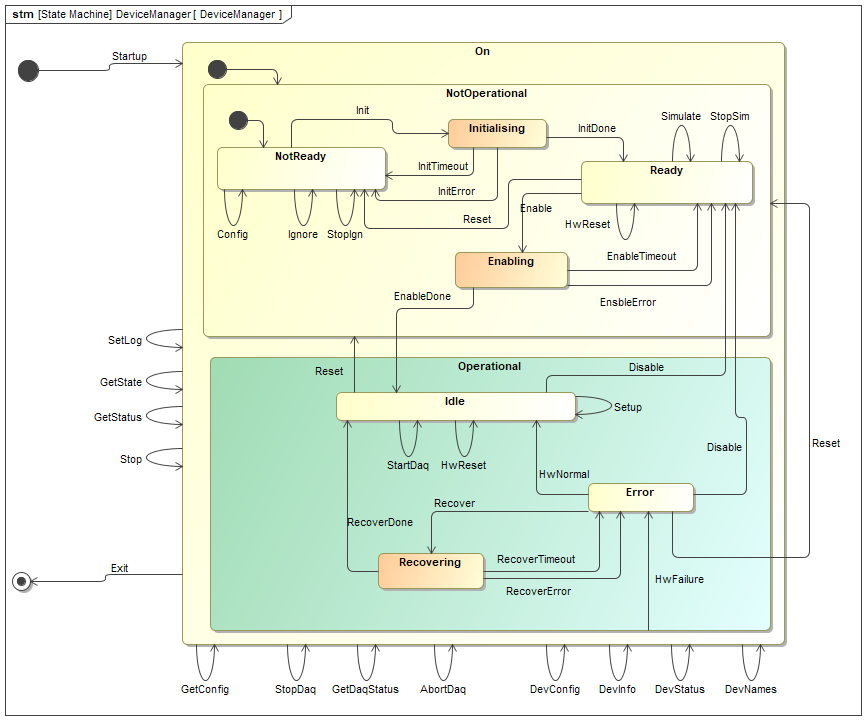

Device Manager State Machine¶

The Device Manager uses a state machine described in a SCXML format that is

interpreted by the state machine engine provided by the rad application framework.

(SCXML specification).

Device Manager State Machine Diagram.¶

Off –> NotReady, event: Startup

The Device Manager starts up and goes automatically to NotOperational/NotReady. Main server objects are instantiated including the basic application that uses the State Machine engine. The Device Manager reads its own configuration and completes its initialisation.

NotReady –> Ready, event: Init

The server connects to each of the device controllers through the device objects. Depending on the device configuration, it establishes the connection to the real HW or to the simulator. If any of the device objects fails to establish the connection, the server will remain in substate NotReady.

NotOperational/Ready –> Operational/Idle, event: Enable

The Device Managers goes through the Enabling state. If Device Controllers are already Operational, the Device Manager does not affect their state and goes immediately to the Operational state. If Device Controllers are not operational, Device Manager will trigger the events (via OPC-UA method calls) to reach the operational state for each of the local devices under the manager control. If it does not succeed within the defined timeout (configuration parameter, see Device Manager Configuration), it will reply with a failure remaining in NotOperational/Ready state. During the transition from NotOperational/Ready to Operational/Idle, the Device Manager downloads the configuration to each Device Controller. If at least one Device Controller cannot reach the Operational state, the Device Manager will remain in state NotOperational/Ready.

Operational/Idle –> Operational/Error, event: HwFailure

Problems in at least one of the managed devices will bring the Device Manager into the Error state (Operational/Error). A typical example would be when the PLC, running the Device Controller, is power-cycled.

Operational/Error –> Operational/Idle, event: HwNormal

In the situation when an error condition is recovered, the Device Manager will go back automatically to Operational/Ready state (event HwNormal). For instance, if the network connection is lost, the Device Manager will go to Error but when the network is restored, the Device Manager will update its state automatically.

Operational –> NotOperational/Ready, event: Disable

The Device Manager disables the operation of devices but the state of controllers is not affected. If the state of the controllers is to be changed to NotReady, this has to be done separately. The reason for the above is to avoid affecting the state of the controllers by changing the state of the manager and thus achieve minimal impact on the hardware. In case of error going from Operational to NotOperational/Ready, the end state will be nevertheless NotOperational/Ready.

NotOperational/Ready –> NotOperational/NotReady, event Reset

The subscription to the OPC-UA server is stopped and the sessions of the managed devices are disconnected. In case of error going from Ready to NotReady, the end state will be nevertheless NotReady.

Extract of the current State Machine specification for the Device Manager.

<state id="On">

<initial>

<transition target="NotOperational"/>

</initial>

<state id="NotOperational">

<initial>

<transition target="NotReady"/>

</initial>

<state id="NotReady">

<transition event="Events.Reset" target="NotReady">

<customActionDomain:ActionReset name="ActionReset"/>

</transition>

<transition event="Events.Init" target="Initialising"/>

<transition event="Events.Config">

<customActionDomain:ActionConfig name="ActionConfig"/>

</transition>

</state>

<state id="Initialising">

<onentry>

<customActionDomain:ActionInitStart name="ActionInitStart"/>

</onentry>

<invoke id="ActivityInitialising"/>

<transition event="Events.InitDone" target="Ready">

<customActionDomain:ActionInitDone name="ActionInitDone"/>

</transition>

<transition event="Events.InitError" target="NotReady">

<customActionDomain:ActionInitError name="ActionInitError"/>

</transition>

Configuration¶

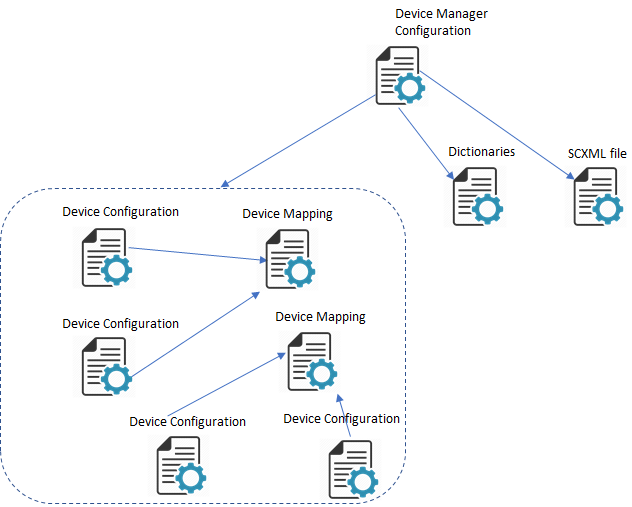

Device Manager Configuration¶

The server configuration is a set of files written in yaml format.

(YAML specification). YAML is easy to read format

that has been adopted temporary until the integration with CII configuration services.

Many resources about YAML can be found on the web. One could also validate the format online, see http://yaml.org/spec/

Note

The entry point for the Device Manager configuration is the file that contains the server configuration and the mapping to the device configuration files. The configuration of each device should be given in a separate file for better readability and maintenance. Each device type uses the corresponding mapping file that defines the real names of the attributes in the OPC-UA address space.

Device Manager configuration files.¶

server_id

This is the id associated with the specific server. This id is used to associate all server configuration parameters as well as the prefix for the DB keys.

<server id>::req_endpoint

This is the endpoint for CII MAL request/reply. The server will listen to incoming commands using this endpoint.

<server id>::pub_endpoint

This is the endpoint for CII MAL pub/sub. The server will publish device topics using this endpoint.

<server id>::db_endpoint

This is the endpoint used by the server for connecting to the Redis DB.

<server id>::db_timeout

This is the server timeout for connecting to the Redis DB.

<server id>::scxml

This is the state machine specification file used by the server.

<server id>::fits_prefix

This is the prefix to be used for the FCS meta-data.

<server id>::devices

This is the list of devices active in the server configuration. Only devices listed here will be managed by the server.

<server id>::cmdtout

General command timeout for sending commands to the Local Control System (LCS).

<device id>::cfgfile

Configuration filename for a device.

<device id>::type

Device type.

An example of a server configuration is provided below.

Warning

Please note that some configuration keywords have been changed from version 1.0 due to the porting to CII MAL. An example of those changes are the configuration parameters req_endpoint and pub_endpoint.

server_id : 'ins1.fcs1'

ins1.fcs1:

req_endpoint : "zpb.rr://127.0.0.1:12082/"

pub_endpoint : "zpb.ps://127.0.0.1:12345/"

db_endpoint : "127.0.0.1:6379"

db_timeout : 2

scxml : "fcf/devmgr/server/sm.xml"

dictionaries : ['dit/stddid/primary.did', 'fcf/devmgr/server/fcf.did']

fits_prefix : "FCS1"

devices : ['lamp1', 'shutter1', 'motor1', 'drot1', 'adc1', 'sensor1']

cmdtout : 60000

shutter1:

type: Shutter

cfgfile: "fcf/devmgr/server/shutter1.yml"

lamp1:

type: Lamp

cfgfile: "fcf/devmgr/server/lamp1.yml"

motor1:

type: Motor

cfgfile: "fcf/devmgr/server/motor1.yml"

drot1:

type: Drot

cfgfile: "fcf/devmgr/server/drot1.yml"

adc1:

type: Adc

cfgfile: "fcf/devmgr/server/adc1.yml"

sensor1:

type: Sensor

cfgfile: "fcf/devmgr/server/sensor1.yml"

Device Base Configuration¶

Each device has a common set of configuration parameters.

<device id>::type

It specifies the type of the device. Valid types are: Shutter, Lamp, Motor, Sensor, Drot, Adc, Piezo and Actuator.

<device id>::interface

It defines the communication interface that will be used by the device. At present, the only valid value is: Softing. This is the name of the OPC-UA toolkit used to communicate to the LCS (PLC). The needed libraries are included in the installation of the ELT standard machine.

<device id>::identifier

It defines the PLC object identifier.

<device id>::namespace

It defines the OPC-UA address space number.

<device id>::prefix

It defines the prefix for the address space nodeId of the device.

<device id>::simulated

Flag indicating if device is simulated.

<device id>::ignored

Flag indicating if the device is ignored. When a device is ignored, the device will ignore most of the commands received by the server until it receives the stop ignoring command (StopIgn).

<device id>::mapfile

File providing the configuration of the attributes in the OPC address space per each of the supported device types.

An example of a mapping file configuration is included below.

Shutter:

cfg:

low_closed: cfg.bActiveLowClosed

low_fault: cfg.bActiveLowFault

low_open: cfg.bActiveLowOpen

low_switch: cfg.bActiveLowSwitch

ignore_closed: cfg.bIgnoreClosed

ignore_fault: cfg.bIgnoreFault

ignore_open: cfg.bIgnoreOpen

initial_state: cfg.bInitialState

timeout: cfg.nTimeout

stat:

state: stat.nState

substate: stat.nSubstate

local: stat.bLocal

error_code: stat.nErrorCode

rpc:

rpcInit: RPC_Init

rpcEnable: RPC_Enable

rpcDisable: RPC_Disable

rpcClose: RPC_Close

rpcOpen: RPC_Open

rpcStop: RPC_Stop

rpcReset: RPC_Reset

Note

With the information contained in the mapping file, combined with the PLC prefix and the namespace, the device obtains the NodeId for each of the attributes and the RPCs defined in the ICD with the device controller.

<device id>::fits_prefix

Prefix used by the device when generating the metadata information. This data is included in the FITS file generated by the server at the end of the exposure.

Shutter Specific Configuration¶

The Shutter device defines a set of configuration parameters that will be transferred

to the device controller running in the LCS (PLC). All these parameters are under the

ctrl_config heading.

Warning

The ctrl_config parameters are downloaded to the device controller when the device is not Operational. If the controller is already Operational, the user shall force the transition from Operational to NotOperational/NotReady and back to Operational.

Config Item |

Type |

Optional |

Default |

Description |

|---|---|---|---|---|

ctrl_config::low_closed |

bool |

yes |

false |

If true, the closed signal is active low. |

ctrl_config::low_fault |

bool |

yes |

false |

If true, the fault signal is active low. |

ctrl_config::low_open |

bool |

yes |

false |

If true, the open signal is active low. |

ctrl_config::low_switch |

bool |

yes |

false |

If true, the switch signal is active low. |

ctrl_config::ignore_closed |

bool |

yes |

false |

If true, the closed signal is ignored. |

ctrl_config::ignore_fault |

bool |

yes |

false |

If true, the fault signal is ignored. |

ctrl_config::ignore_open |

bool |

yes |

false |

If true, the open signal is ignored. |

ctrl_config::initial_state |

bool |

yes |

false |

If true, the initial state for shutter will be open. |

ctrl_config::timeout |

uint |

yes |

3000 [ms] |

Shutter timeout for transitions. |

An example of a shutter configuration is given below.

shutter1:

type: Shutter

interface: Softing

identifier: PLC1 # OPCUA Object Identifier

prefix: MAIN.Shutter1 # OPCUA attribute prefix

simulated: true

ignored: false

address: opc.tcp://134.171.59.98:4

simaddr: opc.tcp://127.0.0.1:7576 # Simulation address

mapfile: "fcf/devmgr/server/mapShutter.yml"

fits_prefix: "SHUT1"

ctrl_config:

low_closed: false # If T, signal is active low

low_fault: false # If T, signal is active low

low_open: false # If T, signal is active low

low_switch: false # If T, signal is active low

ignore_closed: false # If T, ignore the signal

ignore_fault: false # If T, ignore the signal

ignore_open: false # If T, ignore the signal

initial_state: false # If T, initial state is open

timeout: 2000

Lamp Specific Configuration¶

The Lamp device defines a set of configuration parameters that will be transferred

to the device controller running in the LCS (PLC). All these parameters are under the

ctrl_config heading.

Warning

The ctrl_config parameters are downloaded to the device controller when the device is not Operational. If the controller is already Operational, the user shall force the transition from Operational to NotOperational/NotReady and back to Operational.

Config Item |

Type |

Optional |

Default |

Description |

|---|---|---|---|---|

ctrl_config::low_fault |

bool |

yes |

false |

If true, the fault signal is active low. |

ctrl_config::low_on |

bool |

yes |

false |

If true, the on signal is active low. |

ctrl_config::low_switch |

bool |

yes |

false |

If true, the switch signal is active low. |

ctrl_config::ignore_fault |

bool |

yes |

false |

If true, the fault signal is ignored. |

ctrl_config::invert_analog |

bool |

yes |

false |

If true, the analog feedback is active. |

ctrl_config::initial_state |

bool |

yes |

false |

If true, the initial state will be switched on. |

ctrl_config::analog_threshold |

int |

yes |

0 [bits] |

Analog feedback signal threshold |

ctrl_config::analog_range |

uint |

yes |

32767 |

Full range of A/D converter for analog output. |

ctrl_config::cooldown |

uint |

yes |

0 [s] |

Cooldown time. |

ctrl_config::maxon |

uint |

yes |

0 [s] |

Maximum time for the lamp to be On. |

ctrl_config::warmup |

uint |

yes |

0 [s] |

Warmup time. |

ctrl_config::timeout |

uint |

yes |

3000 [ms] |

Lamp timeout for transitions. |

An example of a lamp configuration is given below. This configuration file can be found in module devmgr/server

lamp1:

type: Lamp

interface: Softing

identifier: PLC1 # OPCUA Object Identifier

prefix: MAIN.Lamp1 # OPCUA attribute prefix

simulated: false

ignored: false

address: opc.tcp://134.171.59.98:4840

simaddr: opc.tcp://134.171.12.182:4840 # Simulation address

mapfile: "fcf/devmgr/server/mapLamp.yml"

fits_prefix: "LAMP1"

ctrl_config:

low_fault: false # If T, signal is active low

low_on: false # If T, signal is active low

low_switch: false # If T, signal is active low

initial_state: false # If T, initial state is on

timeout: 2000

Sensor Specific Configuration¶

The sensor devices defines currently no configuration that will be downloaded to the LCS. However, it defines the configuration of the sensor channels. The sensor channels are known only at the server side.

Config Item |

Type |

Optional |

Default |

Description |

|---|---|---|---|---|

readonly |

bool |

yes |

false |

Flag to indicate that sensor will only read the data from the controller without attempting to execute RPC calls. This flag is used for sensors running in commercial devices not running in a PLC but having an embedded OPC-UA server. To be used only in special cases. |

ctrl_config::timeout |

uint |

yes |

3000 [ms] |

Sensor timeout for transitions. |

channels |

vector |

no |

na |

List of channels ids. |

<channel id>::description |

string |

yes |

“” |

Channel description. |

<channel id>::type |

string |

no |

na |

Channel type. Allowed types are: DI (bool), AI (double), II (integer), ST (string). |

<channel id>::header |

bool |

yes |

true |

If true, the channel will be included in the metadata FITS file. |

<channel id>::log |

bool |

yes |

true |

If true, the sensor value will be logged (Not available yet !). |

<channel id>::map |

string |

no |

na |

Channel internal mapping to the name in the LCS. |

<channel id>::prefix |

string |

no |

na |

Channel FITS prefix. |

<channel id>::unit |

string |

yes |

Channel unit. |

An example of a sensor configuration is given below. This configuration file can be found in module devmgr/server. In this case, the sensor device has two channels: ch1 and ch2.

sensor1:

type: Sensor

interface: Softing

identifier: PLC1

prefix: MAIN.IODev1

simulated: false

ignored: false

address: opc.tcp://134.171.59.98:4840

simaddr: opc.tcp://134.171.57.209:4840

mapfile: "fcf/devmgr/server/mapSensor.yml"

fits_prefix: "SENSOR1"

ctrl_config:

timeout: 20000

channels: ['ch1', 'ch2']

ch1:

description: "channel1"

fits_prefix: "CH1 STAT"

type: DI

header: true

log: true

unit: mm

map: di1

ch2:

description: "channel2"

fits_prefix: "CH2 STAT"

type: DI

header: true

log: true

unit: dd

map: di2

Motor Specific Configuration¶

The Motor device defines a set of configuration parameters that will be transferred

to the device controller running in the LCS (PLC). All these parameters are under the

ctrl_config heading.

The motor also defines a set of configuration parameters that are only known at the server level, for instance the named positions of the motor.

Warning

The ctrl_config parameters are downloaded to the device controller when the device is not Operational. If the controller is already Operational, the user shall force the transition from Operational to NotOperational/NotReady and back to Operational.

Config Item |

Type |

Optional |

Default |

Description |

|---|---|---|---|---|

ctrl_config::axis_type |

string |

yes |

LINEAR |

Axis type. Allowed options are: LINEAR, CIRCULAR and CIRCULAR_OPT. |

ctrl_config::min_pos |

double |

yes |

0 [uu] |

Minimum position in user units. |

ctrl_config::max_pos |

double |

yes |

0 [uu] |

Maximum position in user units. |

ctrl_config::velocity |

double |

yes |

1.0 [uu/s] |

Default velocity for moving the motor in position mode |

ctrl_config::active_low_lstop |

bool |

yes |

false |

If true, the Lower Stop signal is active low. |

ctrl_config::active_low_lhw |

bool |

yes |

false |

If true, the Lower Hw signal is active low. |

ctrl_config::active_low_ref |

bool |

yes |

false |

If true, the Reference signal is active low. |

ctrl_config::active_low_index |

bool |

yes |

false |

If true, the Index signal is active low. |

ctrl_config::active_low_ustop |

bool |

yes |

false |

If true, the Upper Stop signal is active low. |

ctrl_config::active_low_uhw |

bool |

yes |

false |

If true, the Upper Hw signal is active low. |

ctrl_config::low_brake |

bool |

yes |

false |

If true, the Brake signal is active low. |

ctrl_config::low_inpos |

bool |

yes |

false |

If true, the In Position signal is active low. |

ctrl_config::backlash |

double |

yes |

0 [uu] |

Backlash compensation. If value is zero means no backlash compensation is active. |

ctrl_config::disable |

bool |

yes |

false |

If true, the power of the motor will be disabled after positioning. |

ctrl_config::lock |

bool |

yes |

false |

If true, the motor position will be locked |

ctrl_config::lock_pos |

double |

yes |

0 [uu] |

Position that will be locked in case lock configuration is activated. |

ctrl_config::lock_tolerance |

double |

yes |

0 [us] |

Tolerance of the lock position |

ctrl_config::tout_init |

int |

yes |

60000 [ms] |

Motor initialisation timeout. |

ctrl_config::tout_move |

int |

yes |

60000 [ms] |

Motor move timeout. |

ctrl_config::tout_switch |

int |

yes |

150000 [ms] |

Motor timeout for going out of the switch during initialisation. |

Motor Initialisation¶

Note

The motor has a set of configuration parameters dedicated to the motor initialisation sequence. The initialisation sequence is downloaded to the LCS only when device controller is not operational.

<device id>::initialisation::sequence

List of motor initialization steps. The allowed steps are:

Step |

Description |

Parameter 1 |

Parameter 2 |

|---|---|---|---|

END |

Finish the sequence, no more actions are performed. |

na |

na |

FIND_INDEX |

Motor moves until finding the index pulse. |

Fast velocity [UU/s] |

Slow velocity [UU/s] |

FIND_REF_LE |

Motor moves until finding lower edge of reference switch. |

Fast velocity [UU/s] |

Slow velocity [UU/s] |

FIND_REF_UE |

Motor moves until finding upper edge of reference switch. |

Fast velocity [UU/s] |

Slow velocity [UU/s] |

FIND_LHW |

Motor moves until finding lower hardware limit. |

Fast velocity [UU/s] |

Slow velocity [UU/s] |

FIND_UHW |

Motor moves until finding upper hardware limit. |

Fast velocity [UU/s] |

Slow velocity [UU/s] |

DELAY |

Motor wait for a fixed amount of time before to continue. |

time in [ms] |

na |

MOVE_ABS |

Motor moves to an absolute position. |

Velocity [UU/s] |

Target position [UU] |

MOVE_REL |

Motor moves to a relative position. |

Velocity [UU/s] |

Target position [UU] |

CALIB_ABS |

Motor calibrates an absolute position. |

Position [UU] |

na |

CALIB_REL |

Motor calibrates a relative position. |

Position [UU] |

na |

CALIB_SWITCH |

Motor calibrates switch position. |

Position [UU] |

na |

Note

Some of the initialisation steps require parameters, for instance the speed of the motor. These parameters are defined together with the initialisation step.

<device id>::initialisation::<init step>::value1

Parameter 1 of the initialisation step.

<device id>::initialisation::<init step>::value2

Parameter 2 of the initialisation step.

Note

In case parameters are not applicable (na) please use 0 instead, for instance END, 0, 0

Named Positions¶

The motor device supports a configuration of named positions that associate specific motor position in user units (UU) to names. The aim of name positions is to facilitate the setting of motor positions by end users.

<device id>::positions::posnames

List of position names ids.

<device id>::positions::<posname id>

Value of the position name in user units (UU).

<device id>::positions::tolerance

Tolerance of the named position in user units (UU). If the actual position is within the tolerance, the device will report the named position otherwise its name will be empty.

Note

An example of a motor configuration is given below. This configuration file can be found in module devmgr/server.

motor1:

type: Motor

interface: Softing

identifier: PLC1 # OPCUA Object Identifier

prefix: MAIN.Synchro1 # OPCUA attribute prefix

simulated: false

ignored: false

address: opc.tcp://134.171.59.98:4840

simaddr: opc.tcp://134.171.57.209:4840 # Simulation address

mapfile: "fcf/devmgr/server/mapMotor.yml"

fits_prefix: "MOT1"

ctrl_config:

velocity: 3.0

min_pos: 0.0

max_pos: 359.0

axis_type: CIRCULAR

active_low_lstop: false

active_low_lhw: false

active_low_ref: true

active_low_index: false

active_low_uhw: true

active_low_ustop: false

brake: false

low_brake: false

low_inpos: false

backlash: 0.0

tout_init: 30000

tout_move: 120000

tout_switch: 10000

initialisation:

sequence: ['FIND_LHW', 'FIND_UHW', 'CALIB_ABS', 'END']

FIND_LHW:

value1: 4.0

value2: 4.0

FIND_UHW:

value1: 4.0

value2: 4.0

CALIB_ABS:

value1: 0.0

value2: 0.0

END:

value1: 0.0

value2: 0.0

positions:

posnames: ['ON', 'OFF']

tolerance: 1.0 # Tolerance in UU

ON: 30.0

OFF: 100.0

Derotator Specific Configuration¶

As for other devices, the Derotator device defines a set of configuration

parameters that will be transferred to the device controller running in the LCS

(PLC). All these parameters are under the ctrl_config heading.

Since the Derotator is just an aggregated motor device, it includes all Motor configuration parameters (see fcf_devmgr_motor_config_ref) plus a few parameters specific to derotators.

Warning

The ctrl_config parameters are downloaded to the device controller when the device is not Operational. If the controller is already Operational, the user shall force the transition from Operational to NotOperational/NotReady and back to Operational.

Config Item |

Type |

Optional |

Default |

Description |

|---|---|---|---|---|

ctrl_config::dir_sign |

int |

yes |

1 |

Motor direction sign |

ctrl_config::focus_sign |

int |

yes |

-1 |

Focus direction sign. |

ctrl_config::trk_period |

int |

yes |

20 [ms] |

Period of the tracking corrections within the PLC. |

ctrl_config::stat_ref |

double |

yes |

0.0 [uu] |

Reference position for stationary mode. |

ctrl_config::sky_ref |

double |

yes |

0.0 [uu] |

Reference position for sky mode. |

ctrl_config::user_ref |

double |

yes |

0.0 [uu] |

Reference position for user mode. |

ctrl_config::user_par1 |

double |

yes |

0.0 |

Specific parameter 1 for user mode. |

ctrl_config::user_par2 |

double |

yes |

0.0 |

Specific parameter 2 for user mode. |

ctrl_config::user_par3 |

double |

yes |

0.0 |

Specific parameter 3 for user mode. |

ctrl_config::user_par4 |

double |

yes |

0.0 |

Specific parameter 4 for user mode. |

Note

An example of a Derotator configuration is given below. This configuration file can be found in module devmgr/server.

drot1:

type: Drot

interface: Softing

identifier: PLC1 # OPCUA Object Identifier

prefix: MAIN_FAST.drot # OPCUA attribute prefix

simulated: false

ignored: false

address: opc.tcp://134.171.59.98:4840

simaddr: opc.tcp://134.171.57.209:4840 # Simulation address

mapfile: "fcf/devmgr/server/mapDrot.yml"

fits_prefix: "DROT1"

ctrl_config:

latitude: -0.429833092

longitude: 1.228800386

velocity: 3.0

min_pos: -359

max_pos: 359.0

axis_type: CIRCULAR

active_low_lstop: false

active_low_lhw: false

active_low_ref: true

active_low_index: false

active_low_uhw: true

active_low_ustop: false

brake: false

low_brake: false

low_inpos: false

backlash: 0.0

tout_init: 30000

tout_move: 120000

tout_switch: 10000

initialisation:

sequence: ['FIND_LHW', 'FIND_UHW', 'CALIB_ABS', 'END']

FIND_LHW:

value1: 4.0

value2: 4.0

FIND_UHW:

value1: 4.0

value2: 4.0

CALIB_ABS:

value1: 0.0

value2: 0.0

END:

value1: 0.0

value2: 0.0

positions:

posnames: ['ON', 'OFF']

tolerance: 1.0 # Tolerance in UU

ON: 30.0

OFF: 100.0

Derotator Control¶

Operation modes¶

Alias |

Name |

Description |

|---|---|---|

eng |

Engineering |

In this mode, the Derotator behaves like a standard motor. This means that it can be moved in user units and encoders. |

stat |

Stationary |

In this mode, the Derotator is stationary and it can be positioned at given angle according to the following formula: pos := stat_ref + dir_sign * (posang)/2.0; |

sky |

Sky |

The Derotator tracks following the field rotation. fieldRotation := parallactic - focus_sign * altitude; pos := sky_ref + dir_sign * (posang - fieldRotation)/2; angleOnSky := posang; modeAngle := angleOnSky; |

elev |

Elevation |

The Derotator tracks following the pupil rotation. pos := elev_ref + (focus_sign * dir_sign * altitude) /2.0; angleOnSky := parallactic; modeAngle := angleOnSky; |

user |

User |

The Derotator tracks according to the user custom computation. |

ADC Specific Configuration¶

As for other devices, the ADC device defines a set of configuration

parameters that will be transferred to the device controller running in the LCS

(PLC). These parameters are under the ctrl_config heading. Considering that

the ADC is a multi-axis device, it includes as well the configuration of two

standard motor devices. The configuration of each motor device is defined

in separate files and they correspond to the configuration of a standard motor

device (see fcf_devmgr_motor_config_ref).

Warning

The ctrl_config parameters are downloaded to the device controller when the device is not Operational. If the controller is already Operational, the user shall force the transition from Operational to NotOperational/NotReady and back to Operational.

Config Item |

Type |

Optional |

Default |

Description |

|---|---|---|---|---|

ctrl_config::axes |

list |

no |

List of motors controlled by the ADC |

|

ctrl_config::trk_period |

int |

yes |

20 [ms] |

Period of the tracking corrections within the PLC. |

ctrl_config::pslope |

double |

yes |

0.0023 [arcsec/mbar] |

Pressure slope. |

ctrl_config::poffset |

double |

yes |

743.0 [mbar] |

Pressure offset. |

ctrl_config::tslope |

double |

yes |

-0.0061 [arcsec/C] |

Temperature slope. |

ctrl_config::toffset |

double |

yes |

12 [C] |

Temperature offset. |

ctrl_config::afactor |

double |

yes |

3.32 [1/arcsec] |

A Factor |

ctrl_config::zdlimit |

double |

yes |

0.0174533 |

Zenith distance limit |

ctrl_config::minelev |

double |

yes |

27.64 [deg] |

Minimum Elevation. |

ctrl_config::mot1_signoff |

int |

yes |

1 |

Motor 1 sign for off mode |

ctrl_config::mot1_signauto |

int |

yes |

1 |

Motor 1 sign for auto mode |

ctrl_config::mot1_signphi |

int |

yes |

1 |

Motor 1 sign for phi |

ctrl_config::mot1_refoff |

double |

yes |

0 [deg] |

Motor 1 offset for off mode |

ctrl_config::mot1_refauto |

double |

yes |

0 [deg] |

Motor 1 offset for auto mode |

ctrl_config::mot1_coffset |

double |

yes |

1.7387 [arcsec] |

Motor 1 C parameter |

ctrl_config::mot1_poffset |

double |

yes |

90 [deg] |

Motor 1 Position offset |

ctrl_config::mot1_drotfactor |

double |

yes |

2 |

Motor 1 derotator offset |

ctrl_config::mot2_signoff |

int |

yes |

1 |

Motor 2 sign for off mode |

ctrl_config::mot2_signauto |

int |

yes |

1 |

Motor 2 sign for auto mode |

ctrl_config::mot2_signphi |

int |

yes |

1 |

Motor 2 sign for phi |

ctrl_config::mot2_refoff |

double |

yes |

0 [deg] |

Motor 2 reference position for off mode |

ctrl_config::mot2_refauto |

double |

yes |

0 [deg] |

Motor 2 reference position for auto mode |

ctrl_config::mot2_coffset |

double |

yes |

1.7387 [arcsec] |

Motor 2 C parameter |

ctrl_config::mot2_poffset |

double |

yes |

90 [deg] |

Motor 2 Position offset |

ctrl_config::mot2_drotfactor |

double |

yes |

2 |

Motor 2 derotator offset |

<motor1>::prefix |

string |

no |

Internal name used by the ADC for motor1 (fixed) |

|

<motor1>::cfgfile |

string |

no |

File path for the motor 1 configuration. |

|

<motor2>::prefix |

string |

no |

Internal name used by the ADC for motor2 (fixed) |

|

<motor2>::cfgfile |

string |

no |

File path for the motor 2 configuration. |

|

Note

An example of an Adc configuration is given below. This configuration file can be found in module devmgr/server.

adc1:

type: Adc

interface: Softing

identifier: PLC1 # OPCUA Object Identifier

prefix: MAIN_FAST.adc # OPCUA attribute prefix

simulated: false

ignored: false

address: opc.tcp://134.171.59.98:4840

simaddr: opc.tcp://134.171.57.209:4840 # Simulation address

mapfile: "fcf/devmgr/server/mapAdc.yml"

fits_prefix: "ADC1"

ctrl_config:

axes: ['adc1_motor1', 'adc1_motor2']

adc1_motor1:

prefix: "motor1"

cfgfile: "devmgr/server/adc1Motor1.yml"

adc1_motor2:

prefix: "motor2"

cfgfile: "devmgr/server/adc1Motor2.yml"

ADC Control¶

Operation modes¶

The ADC operates two motorized functions. In engineering mode, each motor can be controlled independently.

Alias |

Name |

Description |

|---|---|---|

eng |

Engineering |

In this mode, the ADC behaves like the standard motor. This means that each motor can be moved in user units and encoders. |

off |

Off |

In this mode, the ADC is stationary and it can be positioned at given angle according to the following formula: pos := off_ref + sign_off * posang; |

auto |

Auto |

The ADC tracks following the default formula. This formula can be replaced by the user in order to accommodate instrument specific requirements. |

Piezo Specific Configuration¶

The Piezo device defines a set of configuration parameters that will be transferred

to the device controller running in the LCS (PLC). All these parameters are under the

ctrl_config heading.

Warning

The ctrl_config parameters are downloaded to the device controller when the device is not Operational. If the controller is already Operational, the user shall force the transition from Operational to NotOperational/NotReady and back to Operational.

Config Item |

Type |

Optional |

Default |

Description |

|---|---|---|---|---|

ctrl_config::num_axes |

short |

no |

3 |

Configured number of piezo axes. This parameter gives flexibility to adapt to different type of piezos. |

ctrl_config::max_on |

int |

yes |

0 |

Maximum time that outputs will be maintained. If it is zero means there is no time counter. |

ctrl_config::full_range[] |

short |

yes |

32767 |

Full range per axes in bits. |

ctrl_config::home[] |

double |

yes |

0 |

Home position per axes in user units. |

ctrl_config::lower_limit[] |

double |

yes |

0 |

lower limit per axes in user units. |

ctrl_config::upper_limit[] |

double |

yes |

32767 |

upper limit per axes in user units. |

ctrl_config::user_to_bit_input[] |

double |

yes |

3276.7 |

user to bit conversion factor per axes for inputs. |

ctrl_config::user_offset_input[] |

double |

yes |

0 |

user offset per axes for inputs. |

ctrl_config::user_to_bit_output[] |

double |

yes |

3276.7 |

user to bit conversion factor per axes for outputs. |

ctrl_config::user_offset_output[] |

double |

yes |

0 |

user offset per axes for outputs. |

An example of a piezo configuration is provided below.

piezo1:

type: Piezo

interface: Softing

identifier: PLC1 # OPCUA Object Identifier

prefix: MAIN.Piezo1 # OPCUA attribute prefix

simulated: false

address: opc.tcp://134.171.59.98:4840

simaddr: opc.tcp://134.171.57.209:4840 # Simulation address

mapfile: "fcf/devmgr/devices/mapPiezo.yml"

fits_prefix: "MOT1"

ctrl_config:

num_axis: 3

max_on: 0

full_range1: 32767

full_range2: 32767

full_range3: 32767

home1: 0

home2: 0

home3: 0

lower_limit1: 0

lower_limit2: 0

lower_limit3: 0

upper_limit1: 32767

upper_limit2: 32767

upper_limit3: 32767

user_to_bit_input1: 3276.7

user_to_bit_input2: 3276.7

user_to_bit_input3: 3276.7

user_offset_input1: 0

user_offset_input2: 0

user_offset_input3: 0

user_to_bit_output1: 3276.7

user_to_bit_output2: 3276.7

user_to_bit_output3: 3276.7

user_offset_output1: 0

user_offset_output2: 0

user_offset_output3: 0

Actuator Specific Configuration¶

The Actuator is one of the few devices that is not transferring any configuration to the controller in the transition from Ready to Operational. The Actuator assumes to have all the configuration defined in the controller (PLC). For knowing the controller configuration, please refer to the PLC Actuator section.

An example of a actuator configuration is provided below.

actuator1:

type: Actuator

interface: Softing

identifier: PLC1 # OPCUA Object Identifier

prefix: MAIN.Actuator1 # OPCUA attribute prefix

simulated: false

ignored: false

address: opc.tcp://134.171.59.99:4840

simaddr: opc.tcp://134.171.12.182:4840 # Simulation address

mapfile: "fcf/devmgr/server/mapActuator.yml"

fits_prefix: "MECH1"

ctrl_config:

Database Attributes¶

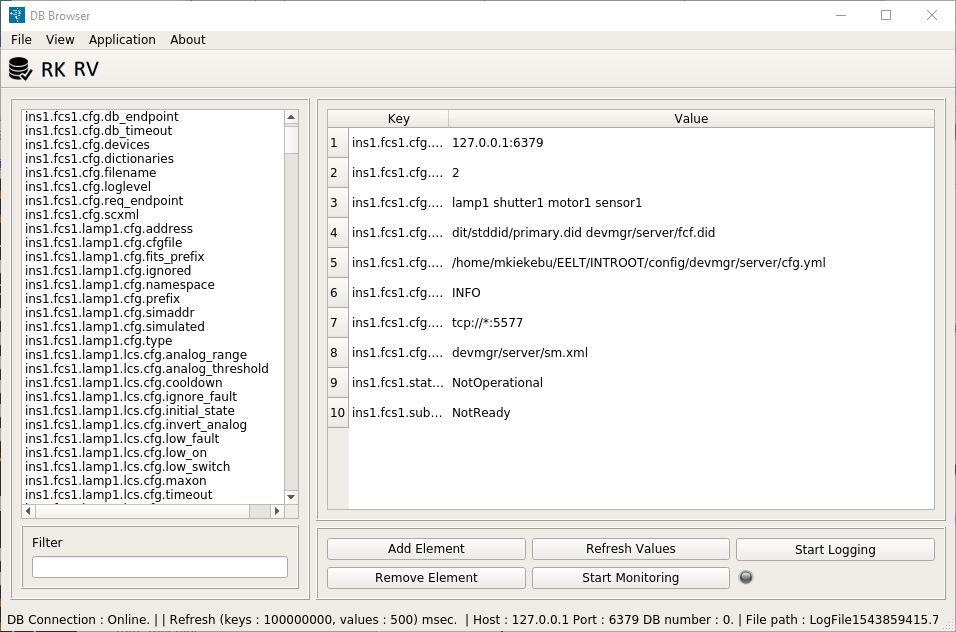

The Device Manager uses the Redis DB to store the actual server configuration and run-time parameters. The Redis keys used by the server follow a hierarchical naming convention starting with the id of the server. Specific keys for devices use the id of the device in the name. The DB keys can be monitored using the dbbrowser utility. All Device Manager keys have a flat structure in Redis DB.

dbbrowser utility¶

Server configuration¶

The server stores the actual values of the server configuration parameters into the Redis DB . This helps to verify whether the configuration has been loaded correctly. For details of the server configuration parameters, see Device Manager Configuration.

Redis Key |

|---|

<instrument id>.<server id>.cfg.db_endpoint |

<instrument id>.<server id>.cfg.db_timeout |

<instrument id>.<server id>.cfg.device |

<instrument id>.<server id>.cfg.dictionaries |

<instrument id>.<server id>.cfg.filename |

<instrument id>.<server id>.cfg.loglevel |

<instrument id>.<server id>.cfg.req_endpoint |

<instrument id>.<server id>.cfg.scxml |

Server Status¶

The server stores the string representation of its state and substate into the Redis DB.

Redis Key |

|---|

<instrument id>.<server id>.state_str |

<instrument id>.<server id>.substate_str |

Common Device Keys¶

Each device has a number of common Redis DB keys.

Redis Key |

|---|

<instrument id>.<server id>.<device id>.cfg.address |

<instrument id>.<server id>.<device id>.cfg.simaddr |

<instrument id>.<server id>.<device id>.cfg.cfgfile |

<instrument id>.<server id>.<device id>.cfg.fits_prefix |

<instrument id>.<server id>.<device id>.cfg.ignored |

<instrument id>.<server id>.<device id>.cfg.simulated |

<instrument id>.<server id>.<device id>.cfg.namespace |

<instrument id>.<server id>.<device id>.cfg.prefix |

<instrument id>.<server id>.<device id>.cfg.type |

Shutter¶

Each shutter device defines a set of specific Redis DB keys:

Redis Key |

|---|

<instrument id>.<server id>.<device id>.lcs.cfg.ignore_closed |

<instrument id>.<server id>.<device id>.lcs.cfg.ignore_fault |

<instrument id>.<server id>.<device id>.lcs.cfg.ignore_open |

<instrument id>.<server id>.<device id>.lcs.cfg.initial_state |

<instrument id>.<server id>.<device id>.lcs.cfg.low_closed |

<instrument id>.<server id>.<device id>.lcs.cfg.low_fault |

<instrument id>.<server id>.<device id>.lcs.cfg.low_open |

<instrument id>.<server id>.<device id>.lcs.cfg.low_switch |

<instrument id>.<server id>.<device id>.lcs.cfg.timeout |

<instrument id>.<server id>.<device id>.lcs.stat.error_code |

<instrument id>.<server id>.<device id>.lcs.stat.error_str |

<instrument id>.<server id>.<device id>.lcs.stat.local |

<instrument id>.<server id>.<device id>.lcs.stat.state |

<instrument id>.<server id>.<device id>.lcs.stat.substate |

Lamp¶

Each lamp device defines a set of specific Redis DB keys:

Redis Key |

|---|

<instrument id>.<server id>.<device id>.lcs.cfg.analog_range |

<instrument id>.<server id>.<device id>.lcs.cfg.analog_threshold |

<instrument id>.<server id>.<device id>.lcs.cfg.cooldown |

<instrument id>.<server id>.<device id>.lcs.cfg.ignore_fault |

<instrument id>.<server id>.<device id>.lcs.cfg.initial_state |

<instrument id>.<server id>.<device id>.lcs.cfg.invert_analog |

<instrument id>.<server id>.<device id>.lcs.cfg.low_fault |

<instrument id>.<server id>.<device id>.lcs.cfg.low_on |

<instrument id>.<server id>.<device id>.lcs.cfg.low_switch |

<instrument id>.<server id>.<device id>.lcs.cfg.maxon |

<instrument id>.<server id>.<device id>.lcs.cfg.timeout |

<instrument id>.<server id>.<device id>.lcs.cfg.warmup |

<instrument id>.<server id>.<device id>.lcs.stat.error_code |

<instrument id>.<server id>.<device id>.lcs.stat.error_str |

<instrument id>.<server id>.<device id>.lcs.stat.intensity |

<instrument id>.<server id>.<device id>.lcs.stat.local |

<instrument id>.<server id>.<device id>.lcs.stat.state |

<instrument id>.<server id>.<device id>.lcs.stat.substate |

Sensor¶

Each sensor device defines a set of specific Redis DB keys:

Redis Key |

|---|

<instrument id>.<server id>.<device id>.cfg.channels.<channel id>.description |

<instrument id>.<server id>.<device id>.cfg.channels.<channel id>.fits_prefix |

<instrument id>.<server id>.<device id>.cfg.channels.<channel id>.header |

<instrument id>.<server id>.<device id>.cfg.channels.<channel id>.log |

<instrument id>.<server id>.<device id>.cfg.channels.<channel id>.map |

<instrument id>.<server id>.<device id>.cfg.channels.<channel id>.type |

<instrument id>.<server id>.<device id>.cfg.channels.<channel id>.unit |

<instrument id>.<server id>.<device id>.lcs.stat.<channel id> |

<instrument id>.<server id>.<device id>.lcs.stat.state |

<instrument id>.<server id>.<device id>.lcs.stat.substate |

Motor¶

Each motor device defines a set of specific Redis DB keys:

Redis Key |

|---|

<instrument id>.<server id>.<device id>.lcs.cfg.active_low_indec |

<instrument id>.<server id>.<device id>.lcs.cfg.active_low_lhw |

<instrument id>.<server id>.<device id>.lcs.cfg.active_low_lstop |

<instrument id>.<server id>.<device id>.lcs.cfg.active_low_ref |

<instrument id>.<server id>.<device id>.lcs.cfg.active_low_uhw |

<instrument id>.<server id>.<device id>.lcs.cfg.active_low_ustop |

<instrument id>.<server id>.<device id>.lcs.cfg.axis_type |

<instrument id>.<server id>.<device id>.lcs.cfg.backlash |

<instrument id>.<server id>.<device id>.lcs.cfg.brake |

<instrument id>.<server id>.<device id>.lcs.cfg.check_inpos |

<instrument id>.<server id>.<device id>.lcs.cfg.disable |

<instrument id>.<server id>.<device id>.lcs.cfg.exec_post_init |

<instrument id>.<server id>.<device id>.lcs.cfg.exec_post_move |

<instrument id>.<server id>.<device id>.lcs.cfg.exec_pre_init |

<instrument id>.<server id>.<device id>.lcs.cfg.exec_pre_move |

<instrument id>.<server id>.<device id>.lcs.cfg.init_seq<number>_action |

<instrument id>.<server id>.<device id>.lcs.cfg.init_seq<number>_value1 |

<instrument id>.<server id>.<device id>.lcs.cfg.init_seq<number>_value2 |

<instrument id>.<server id>.<device id>.lcs.cfg.lock |

<instrument id>.<server id>.<device id>.lcs.cfg.lock_pos |

<instrument id>.<server id>.<device id>.lcs.cfg.lock_tolerance |

<instrument id>.<server id>.<device id>.lcs.cfg.low_brake |

<instrument id>.<server id>.<device id>.lcs.cfg.low_inpos |

<instrument id>.<server id>.<device id>.lcs.cfg.max_pos |

<instrument id>.<server id>.<device id>.lcs.cfg.min_pos |

<instrument id>.<server id>.<device id>.lcs.cfg.tout_init |

<instrument id>.<server id>.<device id>.lcs.cfg.tout_move |

<instrument id>.<server id>.<device id>.lcs.cfg.tout_switch |

<instrument id>.<server id>.<device id>.lcs.cfg.velocity |

<instrument id>.<server id>.<device id>.lcs.stat.axis_brake |

<instrument id>.<server id>.<device id>.lcs.stat.axis_enable |

<instrument id>.<server id>.<device id>.lcs.stat.axis_info_data1 |

<instrument id>.<server id>.<device id>.lcs.stat.inposition |

<instrument id>.<server id>.<device id>.lcs.stat.lock |

<instrument id>.<server id>.<device id>.lcs.stat.ready |

<instrument id>.<server id>.<device id>.lcs.stat.error_code |

<instrument id>.<server id>.<device id>.lcs.stat.error_str |

<instrument id>.<server id>.<device id>.lcs.stat.init_action |

<instrument id>.<server id>.<device id>.lcs.stat.init_step |

<instrument id>.<server id>.<device id>.lcs.stat.initialised |

<instrument id>.<server id>.<device id>.lcs.stat.local |

<instrument id>.<server id>.<device id>.lcs.stat.mode |

<instrument id>.<server id>.<device id>.lcs.stat.pos_actual |

<instrument id>.<server id>.<device id>.lcs.stat.pos_error |

<instrument id>.<server id>.<device id>.lcs.stat.pos_target |

<instrument id>.<server id>.<device id>.lcs.stat.scale_factor |

<instrument id>.<server id>.<device id>.lcs.stat.signal_index |

<instrument id>.<server id>.<device id>.lcs.stat.signal_lhw |

<instrument id>.<server id>.<device id>.lcs.stat.signal_lstop |

<instrument id>.<server id>.<device id>.lcs.stat.signal_ref |

<instrument id>.<server id>.<device id>.lcs.stat.signal_uhw |

<instrument id>.<server id>.<device id>.lcs.stat.signal_ustop |

<instrument id>.<server id>.<device id>.lcs.stat.state |

<instrument id>.<server id>.<device id>.lcs.stat.substate |

<instrument id>.<server id>.<device id>.lcs.stat.vel_actual |

<instrument id>.<server id>.<device id>.pos_actual_name |

<instrument id>.<server id>.<device id>.pos_enc |

<instrument id>.<server id>.<device id>.target_enc |

Derotator¶

The Derotator device uses the same set of Redis keys as the Motor device plus some additional derotator specific ones that are described below:

Redis Key |

|---|

<instrument id>.<server id>.<device id>.lcs.cfg.trk_period |

<instrument id>.<server id>.<device id>.lcs.cfg.user_par1 |

<instrument id>.<server id>.<device id>.lcs.cfg.user_par2 |

<instrument id>.<server id>.<device id>.lcs.cfg.user_par3 |

<instrument id>.<server id>.<device id>.lcs.cfg.user_par4 |

<instrument id>.<server id>.<device id>.lcs.cfg.user_ref |

<instrument id>.<server id>.<device id>.lcs.cfg.sky_ref |

<instrument id>.<server id>.<device id>.lcs.cfg.stat_ref |

<instrument id>.<server id>.<device id>.lcs.stat.angle_on_sky |

<instrument id>.<server id>.<device id>.lcs.stat.alpha |

<instrument id>.<server id>.<device id>.lcs.stat.delta |

<instrument id>.<server id>.<device id>.lcs.stat.track_mode |

ADC¶

The Adc device defines a set of specific Redis keys:

Redis Key |

|---|

<instrument id>.<server id>.<device id>.lcs.cfg.trk_period |

<instrument id>.<server id>.<device id>.lcs.cfg.afactor |

<instrument id>.<server id>.<device id>.lcs.cfg.minelev |

<instrument id>.<server id>.<device id>.lcs.cfg.poffset |

<instrument id>.<server id>.<device id>.lcs.cfg.pslope |

<instrument id>.<server id>.<device id>.lcs.cfg.toffset |

<instrument id>.<server id>.<device id>.lcs.cfg.tslope |

<instrument id>.<server id>.<device id>.lcs.cfg.zdlimit |

<instrument id>.<server id>.<device id>.lcs.cfg.mot1_coffset |

<instrument id>.<server id>.<device id>.lcs.cfg.mot1_drotfactor |

<instrument id>.<server id>.<device id>.lcs.cfg.mot1_poffset |

<instrument id>.<server id>.<device id>.lcs.cfg.mot1_refauto |

<instrument id>.<server id>.<device id>.lcs.cfg.mot1_refoff |

<instrument id>.<server id>.<device id>.lcs.cfg.mot2_coffset |

<instrument id>.<server id>.<device id>.lcs.cfg.mot2_drotfactor |

<instrument id>.<server id>.<device id>.lcs.cfg.mot2_poffset |

<instrument id>.<server id>.<device id>.lcs.cfg.mot2_refauto |

<instrument id>.<server id>.<device id>.lcs.cfg.mot2_refoff |

<instrument id>.<server id>.<device id>.cfg.ignored |

<instrument id>.<server id>.<device id>.cfg.simulated |

<instrument id>.<server id>.<device id>.lcs.stat.alpha |

<instrument id>.<server id>.<device id>.lcs.stat.delta |

<instrument id>.<server id>.<device id>.lcs.stat.error_code |

<instrument id>.<server id>.<device id>.lcs.stat.error_str |

<instrument id>.<server id>.<device id>.lcs.stat.local |

<instrument id>.<server id>.<device id>.lcs.stat.state |

<instrument id>.<server id>.<device id>.lcs.stat.substate |

<instrument id>.<server id>.<device id>.lcs.stat.track_mode |

<instrument id>.<server id>.<device id>.lcs.stat.motor1.axis_brake |

<instrument id>.<server id>.<device id>.lcs.stat.motor1.axis_enable |

<instrument id>.<server id>.<device id>.lcs.stat.motor1.axis_lock |

<instrument id>.<server id>.<device id>.lcs.stat.motor1.local |

<instrument id>.<server id>.<device id>.lcs.stat.motor1.pos_actual |

<instrument id>.<server id>.<device id>.lcs.stat.motor1.pos_enc |

<instrument id>.<server id>.<device id>.lcs.stat.motor1.scale_factor |

<instrument id>.<server id>.<device id>.lcs.stat.motor2.axis_brake |

<instrument id>.<server id>.<device id>.lcs.stat.motor2.axis_enable |

<instrument id>.<server id>.<device id>.lcs.stat.motor2.axis_lock |

<instrument id>.<server id>.<device id>.lcs.stat.motor2.local |

<instrument id>.<server id>.<device id>.lcs.stat.motor2.pos_actual |

<instrument id>.<server id>.<device id>.lcs.stat.motor2.pos_enc |

<instrument id>.<server id>.<device id>.lcs.stat.motor2.scale_factor |

<instrument id>.<server id>.<device id>.motor1.pos_enc |

<instrument id>.<server id>.<device id>.motor2.pos_enc |

Piezo¶

The Piezo device defines a set of specific Redis keys:

Redis Key |

|---|

<instrument id>.<server id>.<device id>.lcs.cfg.full_range1 |

<instrument id>.<server id>.<device id>.lcs.cfg.full_range2 |

<instrument id>.<server id>.<device id>.lcs.cfg.full_range3 |

<instrument id>.<server id>.<device id>.lcs.cfg.home1 |

<instrument id>.<server id>.<device id>.lcs.cfg.home2 |

<instrument id>.<server id>.<device id>.lcs.cfg.home3 |

<instrument id>.<server id>.<device id>.lcs.cfg.lower_limit1 |

<instrument id>.<server id>.<device id>.lcs.cfg.lower_limit2 |

<instrument id>.<server id>.<device id>.lcs.cfg.lower_limit3 |

<instrument id>.<server id>.<device id>.lcs.cfg.upper_limit1 |

<instrument id>.<server id>.<device id>.lcs.cfg.upper_limit2 |

<instrument id>.<server id>.<device id>.lcs.cfg.upper_limit3 |

<instrument id>.<server id>.<device id>.lcs.cfg.max_on |

<instrument id>.<server id>.<device id>.lcs.cfg.num_axes |

<instrument id>.<server id>.<device id>.lcs.cfg.user_offset_input1 |

<instrument id>.<server id>.<device id>.lcs.cfg.user_offset_input2 |

<instrument id>.<server id>.<device id>.lcs.cfg.user_offset_input3 |

<instrument id>.<server id>.<device id>.lcs.cfg.user_to_bit_input1 |

<instrument id>.<server id>.<device id>.lcs.cfg.user_to_bit_input2 |

<instrument id>.<server id>.<device id>.lcs.cfg.user_to_bit_input3 |

<instrument id>.<server id>.<device id>.lcs.cfg.user_offset_output1 |

<instrument id>.<server id>.<device id>.lcs.cfg.user_offset_output2 |

<instrument id>.<server id>.<device id>.lcs.cfg.user_offset_output3 |

<instrument id>.<server id>.<device id>.lcs.cfg.user_to_bit_output1 |

<instrument id>.<server id>.<device id>.lcs.cfg.user_to_bit_output2 |

<instrument id>.<server id>.<device id>.lcs.cfg.user_to_bit_output3 |

<instrument id>.<server id>.<device id>.lcs.stat.actual_pos_bit1 |

<instrument id>.<server id>.<device id>.lcs.stat.actual_pos_bit2 |

<instrument id>.<server id>.<device id>.lcs.stat.actual_pos_bit3 |

<instrument id>.<server id>.<device id>.lcs.stat.actual_pos_user1 |

<instrument id>.<server id>.<device id>.lcs.stat.actual_pos_user2 |

<instrument id>.<server id>.<device id>.lcs.stat.actual_pos_user3 |

<instrument id>.<server id>.<device id>.lcs.stat.error_codes |

<instrument id>.<server id>.<device id>.lcs.stat.error_str |

<instrument id>.<server id>.<device id>.lcs.stat.local |

<instrument id>.<server id>.<device id>.lcs.stat.state |

<instrument id>.<server id>.<device id>.lcs.stat.substate |

Actuator¶

Each actuator device defines a set of specific Redis DB keys:

Redis Key |

|---|

<instrument id>.<server id>.<device id>.lcs.stat.local |

<instrument id>.<server id>.<device id>.lcs.stat.state |

<instrument id>.<server id>.<device id>.lcs.stat.substate |

<instrument id>.<server id>.<device id>.lcs.stat.error_code |

<instrument id>.<server id>.<device id>.lcs.stat.error_str |

Commands¶

The commands currently supported by the server are listed here: List of Commands.

Error Handling¶

FCF Commands throw exceptions in case of errors or timeouts. Client applications can catch the exceptions and obtain the error message associated with the function getDesc(). This error does not contain neither the history nor the error stack but it normally indicates precisely where the error occurred.

try {

auto reply = client->GetStatus();

} catch (const fcfif::ExceptionErr& e) {

RAD_LOG_ERROR() << "Error reply " << e.getDesc() << ").";

}

Serialization¶

The Device Manager uses the CII MAL ZPB (ZeroMQ + Google Proto buffers) for serialising commands.

Note

Each command has two parts: a payload and its corresponding reply, see the details in the fcfif module. The normal replies are plain strings.

Setup Command¶

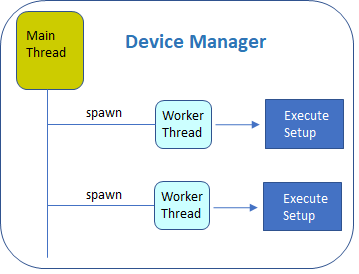

The Setup command is intended to produce a change in the run-time configuration. It is also a way of triggering operational actions on the devices. It is possible to switch a lamp on, close a shutter and move a motor in separate messages or within the same one. This means that the content of the message varies. The devices will de-serialise the message and communicate the actions to be taken to the corresponding PLCs via the interface with the LCS.

The DevMgr is not blocked when receiving concurrent Setup commands (messages). It executes them in separate worker threads that are spawned per each new Setup command. The threads will be running until the commands have been executed successfully, an error occured, the timeout has elapsed or a Stop command is received, see figure below.

Device Manager Setup worker threads.¶

Note

A Stop command finalizes all ongoing worker threads that are being handled by the Device Manager.

Warning

Conflicting requests across different Setup commands running in parallel are not handled by the Device Manager. They are pushed down to the PLC. The PLC is resolving them depending on the actual status. This means that, if the user sends two consecutive commands with conflicting requests, most likely the second one will get an error from the PLC. The exact behaviour will depend on the specific Device Controller implementation.

The interface definition of the Setup command can be found in module fcfif. The payload is based on an array of unions. The union may contain any device supported by the Device Manager.

<union name="DeviceUnion">

<discriminator type="nonBasic" nonBasicTypeName="DeviceType" />

<case>

<caseDiscriminator value ="SHUTTER"/>

<member name="shutter" type="nonBasic" nonBasicTypeName="ShutterDevice" />

</case>

<case>

<caseDiscriminator value ="LAMP"/>

<member name="lamp" type="nonBasic" nonBasicTypeName="LampDevice" />

</case>

<case>

<caseDiscriminator value ="MOTOR"/>

<member name="motor" type="nonBasic" nonBasicTypeName="MotorDevice" />

</case>

<case>

<caseDiscriminator value ="DROT"/>

<member name="drot" type="nonBasic" nonBasicTypeName="DrotDevice" />

</case>

<case>

<caseDiscriminator value ="ADC"/>

<member name="adc" type="nonBasic" nonBasicTypeName="AdcDevice" />

</case>

<case>

<caseDiscriminator value ="PIEZO"/>

<member name="piezo" type="nonBasic" nonBasicTypeName="PiezoDevice" />

</case>

<case>

<caseDiscriminator value ="ACTUATOR"/>

<member name="actuator" type="nonBasic" nonBasicTypeName="ActuatorDevice" />

</case>

<case>

<caseDiscriminator value ="CUSTOM"/>

<member name="custom" type="nonBasic" nonBasicTypeName="CustomDevice" />

</case>

</union>

Warning

The array does not have a fixed size but it has a limit of 100 elements. A limit is needed by the CII XML ICD.

<method name="Setup" returnType="string" throws="ExceptionErr">

<argument name="payload" type="nonBasic" nonBasicTypeName="SetupElem" arrayDimensions="(100)"/>

</method>

Each device structure may contain parameters and one action per device that can be serialized. An example of the device ICD is shown below.

<struct name="ShutterDevice">

<member name="id" type="string" />

<member name="action" type="nonBasic" nonBasicTypeName="ActionShutter" />

</struct>

<struct name="LampDevice">

<member name="id" type="string" />

<member name="intensity" type="double" />

<member name="time" type="uint32_t" />

<member name="action" type="nonBasic" nonBasicTypeName="ActionLamp" />

</struct>

<struct name="BaseMotorDevice">

<member name="id" type="string" />

<member name="name" type="string" />

<member name="pos" type="double" />

<member name="enc" type="int64_t" />

<member name="speed" type="double" />

<member name="unit" type="nonBasic" nonBasicTypeName="MotorPosUnit" />

</struct>

<struct name="MotorDevice" baseType="BaseMotor">

<member name="action" type="nonBasic" nonBasicTypeName="ActionMotor" />

</struct>

<struct name="DrotDevice" baseType="BaseMotor">

<member name="mode" type="nonBasic" nonBasicTypeName="ModeDrot" />

<member name="action" type="nonBasic" nonBasicTypeName="ActionDrot" />

</struct>

<struct name="AdcDevice" baseType="BaseMotor">

<member name="axis" type="nonBasic" nonBasicTypeName="AxesAdc" />

<member name="mode" type="nonBasic" nonBasicTypeName="ModeAdc" />

<member name="action" type="nonBasic" nonBasicTypeName="ActionAdc" />

</struct>

<struct name="PiezoDevice">

<member name="id" type="string" />

<member name="bit1" type="uint32_t" />

<member name="bit2" type="uint32_t" />

<member name="bit3" type="uint32_t" />

<member name="pos1" type="double" />

<member name="pos2" type="double" />

<member name="pos3" type="double" />

<member name="action" type="nonBasic" nonBasicTypeName="ActionPiezo" />

</struct>

<struct name="ActuatorDevice">

<member name="id" type="string" />

<member name="action" type="nonBasic" nonBasicTypeName="ActionActuator" />

</struct>

<struct name="CustomDevice">

<member name="parameters" type="string" />

</struct>

Note

The CustomDevice is to be used for implementing custom devices where the payload data can be

serialized in JSON. The serialization shall be done by the client applications using the parameters

in the CustomDevice structure to carry the information encoded in JSON. The above enables extendability

without the need to provide specific CII XML ICDs which is a significant simplification for instruments.

Status Command¶

The status command provides information about each device controlled by the Device Manager. An example of the output generated by the Status command is shown below.

$ fcfClient zpb.rr://127.0.0.1:12083 GetStatus ""

shutter1.simulated = true

shutter1.lcs.state = Operational

shutter1.lcs.substate = Close

lamp1.simulated = true

lamp1.lcs.state = Operational

lamp1.lcs.substate = Off

lamp1.lcs.intensity = 0.000000

motor1.simulated = true

motor1.lcs.state = Operational

motor1.lcs.substate = Standstill

motor1.lcs.pos_target = 30.000000

motor1.lcs.pos_actual = 30.002197

motor1.lcs.vel_actual = 0.000000

motor1.lcs.axis_enable = true

motor1.pos_actual_name = ON

motor1.pos_enc = 341

OK

The user could request the status of a specific device or a subset of the devices, see below.

$ fcfClient zpb.rr://127.0.0.1:12083 GetStatus "motor1"

motor1.simulated = true

motor1.lcs.state = Operational

motor1.lcs.substate = Standstill

motor1.lcs.pos_target = 30.000000

motor1.lcs.pos_actual = 30.002197

motor1.lcs.vel_actual = 0.000000

motor1.lcs.axis_enable = true

motor1.pos_actual_name = ON

motor1.pos_enc = 341

OK

$ fcfClient zpb.rr://127.0.0.1:12083 GetStatus "lamp1, motor1"

lamp1.simulated = true

lamp1.lcs.state = Operational

lamp1.lcs.substate = Off

lamp1.lcs.intensity = 0.000000

motor1.simulated = true

motor1.lcs.state = Operational

motor1.lcs.substate = Standstill

motor1.lcs.pos_target = 30.000000

motor1.lcs.pos_actual = 30.002197

motor1.lcs.vel_actual = 0.000000

motor1.lcs.axis_enable = true

motor1.pos_actual_name = ON

motor1.pos_enc = 341

OK

Note

The list of devices is comma-separated.

Ignore Command¶

This command tells the Device Manager to completely ignore a device. It can be used when there are hardware failures or when the hardware is not yet available. The following example shows a sequence that ignores device lamp1, gets the status of the devices and then stops ignoring the device.

Note

When a device is ignored, no other information is provided for this device when processing the status command.

$ fcfClient zpb.rr://127.0.0.1:12083 Ignore "lamp1"

$ fcfClient zpb.rr://127.0.0.1:12083 Status "lamp1"

lamp1.ignored = true

OK

$ fcfClient zpb.rr://127.0.0.1:12083 StopIgn "lamp1"

$ fcfClient zpb.rr://127.0.0.1:12083 Status "lamp1"

lamp1.simulated = true

lamp1.lcs.state = Operational

lamp1.lcs.substate = Off

lamp1.lcs.intensity = 0.000000

OK

Simulate Command¶

This command tells the Device Manager to use the simulation address of the device. If the Device Manager is already connected, it will disconnect from the normal address and connect to the simulator. When the simulation is stopped, the server reverts the action and the device is back to normal mode.

The purpose of the simulation is to be able to validate the response of the Device Manager under different error conditions. It also allows to test the high-level SW when the HW is not yet available.

$ fcfClient zpb.rr://127.0.0.1:12083 Simulate "lamp1"

$ fcfClient zpb.rr://127.0.0.1:12083 Status "lamp1"

lamp1.simulated = true

lamp1.lcs.state = Operational

lamp1.lcs.substate = Off

lamp1.lcs.intensity = 0.000000

OK

$ fcfClient zpb.rr://127.0.0.1:12083 StopSim "lamp1"

$ fcfClient zpb.rr://127.0.0.1:12083 Status "lamp1"

lamp1.lcs.state = Operational

lamp1.lcs.substate = Off

lamp1.lcs.intensity = 0.000000

OK

Troubleshooting¶

Logging¶

The Device Manager has implemented six logging levels that provide additional information for troubleshooting to the developer.

Name |

Verbosity |

Description |

|---|---|---|

ERROR |

very low |

Provide logging only in case of errors. |

INFO |

low |

Provide information for the most important actions (default). |

DEBUG |

medium |

Provide additional information for the developer. |

DEBUG2 |

high |

Includes more details such as Node IDs of OPC-UA attributes |

DEBUG3 |

high |

Includes the logging of each subscription event. |

TRACE |

very high |

Includes all the function tracing. |

To activate a new logging, the command SetLog shall be used. See the example below.

$ fcfClient zpb.rr://127.0.0.1:12083 SetLog "TRACE"

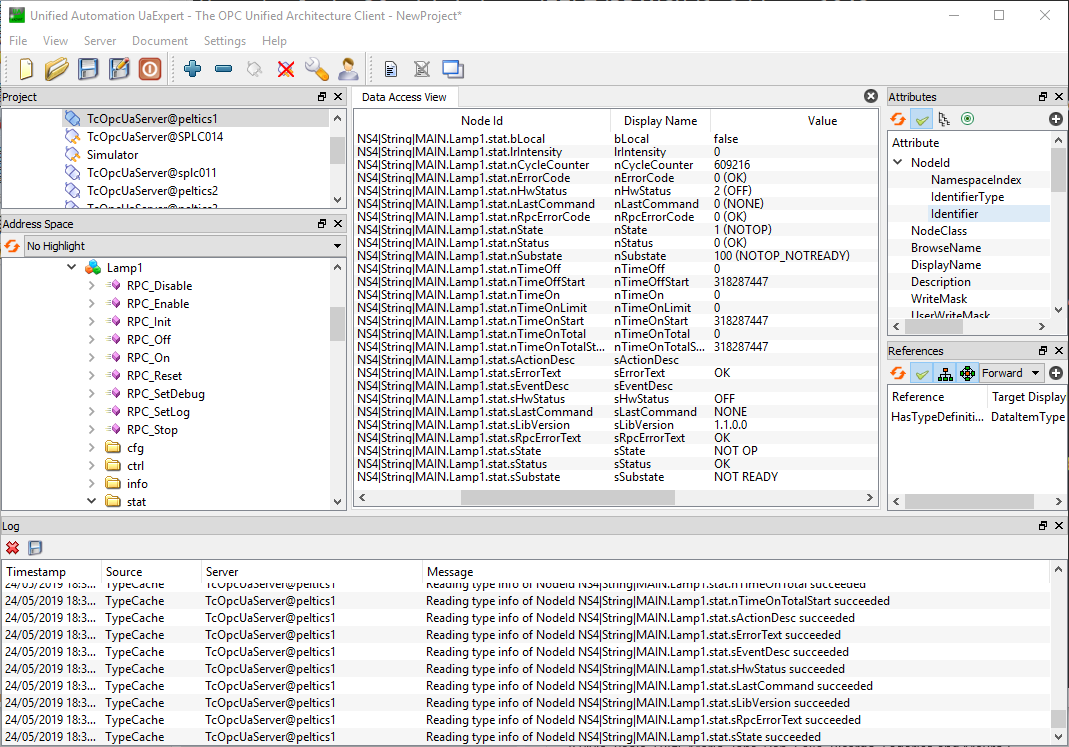

OPC-UA Client¶

Sometimes it is better to check the status of the PLC using an OPC-UA client. One of the best tools available is the UaExpert from Unified Automation. This tool enables the control and monitoring of all device variables independently of the Device Manager. The user can trigger the execution of RPCs and monitor the device state changes. The UaExpert is an essential tool for troubleshooting.

UaExpert OPC-UA client.¶