|

|

EUROPEAN

SOUTHERN OBSERVATORY

Organisation Europ�enne pour des Recherches Astronomiques dans l'H�misph�re

Austral

Europ�ische Organisation f�r astronomische Forschung in der s�dlichen

Hemisph�re

VLT PROGRAMME

VERY

LARGE TELESCOPE

VLT

Software

---

VLT

Instrumentation Software

Template

for Functional Specification

Doc. No.: VLT-SPE-ESO-17240-3222

Issue: 3

Date: 30/09/2005

Name������������������������������������������������������ Date������������������������ Signature

��������������� Prepared:� A.Longinotti����������������������������������������������������� 30/09/2005

Name������������������������������������������������������ Date������������������������ Signature

��������� Approved:� K.Wirenstrand��������������������������������������������������������������� �

Name������������������������������������������������������ Date������������������������ Signature

��������������� Released:� M.Cullum������������������������������������������� ��

VLT PROGRAMME * TELEPHONE:

(089) 3 20 06-0 * FAX: (089) 3 20 06 514

CHANGE RECORD

|

ISSUE |

DATE |

SECTION/PAGE AFFECTED |

REASON/INITIATION DOCUMENTS/REMARKS |

|

1 |

|

All |

First issue |

|

2 |

|

4.13 5.14 6.17 |

ic0SelfTest� replaced with inscSelfTest module xxd removed, as test sw moved (VLTSW20040158) test code moved from xxo (VLTSW20040158) |

|

3 |

|

10.2 10.3 |

Moved to Sw Management Plan template document (VLT-PLA-ESO-17240-3786) |

TABLE OF CONTENTS

TABLE OF CONTENTS������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������� 3

1�� INTRODUCTION������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������ 6

1.1 PURPOSE���������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������� 6

1.2 Scope����������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������� 6

1.3 Applicable Documents������������������������������������������������������������������������������������������������������������������������������������������������������������������������������ 6

1.4 Reference Documents������������������������������������������������������������������������������������������������������������������������������������������������������������������������������� 7

1.5 Abbreviations and Acronyms����������������������������������������������������������������������������������������������������������������������������������������������������������������� 7

1.6 Glossary������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������� 8

1.7 Stylistic Conventions�������������������������������������������������������������������������������������������������������������������������������������������������������������������������������� 9

1.8 Naming Conventions��������������������������������������������������������������������������������������������������������������������������������������������������������������������������������� 9

1.9 Problem Reporting/Change Request������������������������������������������������������������������������������������������������������������������������������������������������������� 9

1.10��� Graphical notation�������������������������������������������������������������������������������������������������������������������������������������������������������������������������������� 9

2�� OVERVIEW������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������� 11

2.1 Instrument ID and prefix������������������������������������������������������������������������������������������������������������������������������������������������������������������������� 11

2.2 Hardware architecture����������������������������������������������������������������������������������������������������������������������������������������������������������������������������� 11

2.2.1�� Instrument LAN���������������������������������������������������������������������������������������������������������������������������������������������������������������������������� 11

2.3 Software architecture������������������������������������������������������������������������������������������������������������������������������������������������������������������������������� 12

2.3.1�� INS environments������������������������������������������������������������������������������������������������������������������������������������������������������������������������� 13

2.3.2�� INS users���������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������� 13

3�� ANALYSIS��������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������� 15

3.1 Use cases�������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������� 15

3.1.1�� Scientific Operations�������������������������������������������������������������������������������������������������������������������������������������������������������������������� 15

3.1.2�� Target Acquisition����������������������������������������������������������������������������������������������������������������������������������������������������������������������� 15

3.1.3�� Instrument Setup�������������������������������������������������������������������������������������������������������������������������������������������������������������������������� 16

3.1.4�� Exposure execution����������������������������������������������������������������������������������������������������������������������������������������������������������������������� 17

3.1.5�� Filter substitution������������������������������������������������������������������������������������������������������������������������������������������������������������������������� 18

4�� INSTRUMENT CONTROL

SOFTWARE (ICS)������������������������������������������������������������������������������������������������������������������������������������ 19

4.1 Devices������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������ 19

4.1.1�� Special devices������������������������������������������������������������������������������������������������������������������������������������������������������������������������������ 21

4.1.2�� Cryogenics������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������� 21

4.1.3�� Backlash compensation��������������������������������������������������������������������������������������������������������������������������������������������������������������� 21

4.1.4�� Parallelism�������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������� 21

4.2 Assemblies������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������ 21

4.3 States��������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������� 21

4.4 Commands������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������� 21

4.5 Parameters������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������� 22

4.5.1�� Setup����������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������� 22

4.5.2�� Status���������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������� 22

4.6 Configuration�������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������� 22

4.7 FITS header keywords���������������������������������������������������������������������������������������������������������������������������������������������������������������������������� 22

4.8 Stand-alone mode������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������ 22

4.9 Logging����������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������� 23

4.10��� Safety���������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������� 23

4.10.1 Interlocks��������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������� 23

4.10.2 Warnings��������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������� 23

4.10.3 Alarms�������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������� 23

4.11��� Simulation�������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������� 24

4.12��� Performance����������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������� 24

4.12.1 Initialization����������������������������������������������������������������������������������������������������������������������������������������������������������������������������������� 24

4.12.2 Setup����������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������� 24

4.13��� Test Software�������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������� 24

4.14��� Standards��������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������� 24

4.15��� Modules����������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������� 24

5�� DETECTOR CONTROL

SOFTWARE (DCS)��������������������������������������������������������������������������������������������������������������������������������������� 25

5.1 Data������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������ 25

5.1.1�� Acquisition������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������ 25

5.1.2�� Processing������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������� 25

5.1.3�� Display������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������� 25

5.2 States��������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������� 25

5.3 Commands������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������� 25

5.4 Parameters������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������� 25

5.4.1�� Setup����������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������� 25

5.4.2�� Status���������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������� 25

5.5 Configuration�������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������� 26

5.6 FITS header keywords���������������������������������������������������������������������������������������������������������������������������������������������������������������������������� 26

5.7 Stand-alone mode������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������ 26

5.8 Logging����������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������� 26

5.9 Failure Mode Operation�������������������������������������������������������������������������������������������������������������������������������������������������������������������������� 26

5.10��� Simulation�������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������� 26

5.11��� Performance����������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������� 26

5.11.1 Data rates��������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������� 26

5.11.2 Real-Time Display������������������������������������������������������������������������������������������������������������������������������������������������������������������������� 26

5.12��� Test Software�������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������� 26

5.13��� Standards��������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������� 27

5.14��� Modules����������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������� 27

6�� OBSERVATION SOFTWARE

(OS)������������������������������������������������������������������������������������������������������������������������������������������������������� 28

6.1 Modes�������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������� 28

6.2 Exposure Types���������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������� 28

6.3 Processes�������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������� 28

6.3.1�� OS Server��������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������� 28

6.3.2�� OS Archiver����������������������������������������������������������������������������������������������������������������������������������������������������������������������������������� 28

6.3.3�� OS Special processes������������������������������������������������������������������������������������������������������������������������������������������������������������������� 29

6.4 States��������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������� 29

6.5 Commands������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������� 29

6.6 Parameters������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������� 29

6.6.1�� Setup����������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������� 29

6.6.2�� Status���������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������� 29

6.7 Configuration�������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������� 29

6.8 FITS header keywords���������������������������������������������������������������������������������������������������������������������������������������������������������������������������� 29

6.9 Interface to TCS��������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������� 29

6.10��� User Interface�������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������� 29

6.11��� Logging������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������ 29

6.12��� Archive������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������� 29

6.13��� Templates��������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������� 32

6.13.1 Instrument package���������������������������������������������������������������������������������������������������������������������������������������������������������������������� 32

6.14��� Performance����������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������� 32

6.14.1 Exposure life cycle������������������������������������������������������������������������������������������������������������������������������������������������������������������������ 33

6.15��� Test Software�������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������� 33

6.16��� Standards��������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������� 33

6.17��� Modules����������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������� 33

7�� MAINTENANCE SOFTWARE

(MS)������������������������������������������������������������������������������������������������������������������������������������������������������� 34

7.1 Configuration�������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������� 34

7.2 Templates�������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������� 34

7.2.1�� Instrument technical package����������������������������������������������������������������������������������������������������������������������������������������������������� 35

7.3 Performance���������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������� 35

7.3.1�� Data processing���������������������������������������������������������������������������������������������������������������������������������������������������������������������������� 35

7.4 Test Software�������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������� 35

7.5 Standards�������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������� 35

7.6 Modules���������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������� 35

8�� OBSERVER SUPPORT

SOFTWARE (OSS)���������������������������������������������������������������������������������������������������������������������������������������� 36

8.1 Standards�������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������� 36

8.2 Modules���������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������� 36

9�� SYSTEM ATTRIBUTES���������������������������������������������������������������������������������������������������������������������������������������������������������������������������� 37

9.1 Installation������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������ 37

9.2 Startup/Shutdown������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������ 37

9.3 User Station���������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������� 37

9.4 Security������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������ 37

9.5 Availability������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������ 37

9.6 Maintainability����������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������� 37

9.7 Documentation����������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������� 38

9.8 Adaptability and enhancement potential��������������������������������������������������������������������������������������������������������������������������������������������� 38

9.9 Training����������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������� 38

10 DEVELOPMENT

AND TEST FACTORS����������������������������������������������������������������������������������������������������������������������������������������������� 39

10.1��� Project Control������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������ 39

10.2��� Test������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������������� 39

11 Traceability

matrix������������������������������������������������������������������������������������������������������������������������������������������������������������������������ 40

This document aims to

provide Instrument Software Engineers with a template of the Instrument

Software Functional Specification (ISFS) document. Instrument specific ISFS

documents should be based on this template. They should contain at least the structure and information

described herein (whenever applicable), and possibly add instrument specific

parts.

In the present

document, XXXX is used to indicate the name of a generic instrument.

Examples appearing in

this document are taken from existing ISFS.

Paragraphs in italics should be removed or at least adapted to the

specific instrument.

The purpose of this document is to describe the Functional Specifications of the XXXX Control Software. They are the result of the analysis study of the requirements, described in [AD 11], and [AD 02].

This document logically follows the Instrument Software User Requirements Specification (ISURS, see [AD 11]) and shall be applicable to all the following Software documents, in particular the Instrument Software Design Description (ISDD), which logically directly follows it

In order to trace more easily all requirements and related design solutions in the next Software documents, all major points described here have a numbered tag: [ISFS nn].

This document shall be

reviewed at the Preliminary Design Review (PDR). It shall be part of the PDR

data package. In case of exceptional changes to the requirements after PDR,

once the change request has been approved by ESO, the ISURS and this document

shall be updated accordingly.

This document defines the Functional Specifications of the XXXX Control Software only. Functional Specifications of other parts of the VLT data flow, such as the pipeline, are outside its scope.

The following documents, of the exact issue shown, form a part of this document to the extent specified herein. In the event of conflict between the documents referenced herein and the contents of this document, the contents of this document shall be considered as a superseding requirement.

|

Reference |

Document Number |

Issue |

Date |

Title |

|

VLT-SPE-ESO-xxxxx-xxxx |

1 |

xx/xx/xxxx |

XXXX Technical Specification |

|

|

VLT-SPE-ESO-17212-0001 |

5 |

|

Instrumentation Software Specification |

|

|

VLT-SPE-ESO-17240-0385 |

4 |

|

INS Common Software Specification |

|

|

VLT-SPE-ESO-10000-2723 |

1 |

|

VLT Requirements for Scientific Instruments |

|

|

VLT-PRO-ESO-10000-0228 |

1 |

|

VLT Software Programming Standards |

|

|

VLT-SPE-ESO-xxxxx-xxxx |

1 |

xx/xx/xxxx |

XXXX Control Electronics Specification |

|

|

VLT-ICD-ESO-17240-19200 |

1.3 |

|

ICD between VCS and OH |

|

|

VLT-ICD-ESO-17240-19400 |

2.6 |

|

ICD between VCS and Archive |

|

|

VLT-PLA-ESO-10000-0441 |

1.0 |

|

VLT Science Operation Plan |

|

|

GEN-SPE-ESO-19400-0794 |

3 |

|

Data Interface Control Document |

|

|

VLT-SPE-ESO-xxxx-xxxx |

1 |

xx/xx/xxxx |

XXXX Control Software User Requirements |

The following documents are referenced in this document.

|

Reference |

Document Number |

Issue |

Date |

Title |

|

VLT-MAN-ESO-17200-0888 |

1.0 |

|

VLT Common Software Overview |

|

|

VLT-MAN-ESO-17200-0642 |

4 |

|

VLT Common Software Installation Manual |

|

|

VLT-MAN-ESO-17230-0942 |

2 |

|

TCS User Manual |

|

|

VLT-PLA-ESO-17240-2266 |

5 |

|

INS Acceptance Test Plan Template Document |

|

|

VLT-MAN-ESO-17200-0981 |

2 |

|

VLT Problem Report Change Request User |

|

|

G. Booch,

|

|

10/1998 |

The Unified Modelling Language User Guide |

|

|

VLT-MAN-ESO-17240-0934 |

5 |

|

INS Common sw - Base ICS User Manual |

|

|

VLT-MAN-ESO-17240-2240 |

4 |

|

INS Common sw for Templates User Manual |

|

|

VLT-MAN-ESO-13640-1388 |

3 |

|

FIERA Control Software User Manual |

|

|

VLT-MAN-ESO-17240-2265 |

4 |

|

INS Common sw - Base OS Stub User Manual |

|

|

VLT-MAN-ESO-17220-1332 |

4 |

|

HOS/Broker for Observation Blocks User Manual |

|

|

VLT-MAN-ESO-17240-1973 |

5 |

|

Template Instrument User and Maint.Manual |

|

|

VLT-PLA-ESO-xxxx-xxxx |

1 |

xx/xx/xxxx |

XXXX Software Management Plan |

|

|

VLT-MAN-ESO-17210-0619 |

2.4 |

|

Central Control Software User Manual |

|

|

VLT-MAN-ESO-14100-1878 |

1.4 |

|

IRACE-DCS User Manual |

1.5 Abbreviations and Acronyms

This document employs several abbreviations and acronyms to refer concisely to an item, after it has been introduced. The following list is aimed to help the reader in recalling the extended meaning of each short expression:

|

ADC |

Analogue to Digital Converter |

|

AIV |

Assembly, Integration and Verification |

|

API |

Application Programmatic Interface |

|

ATM |

Asynchronous Transfer Mode |

|

ATP |

Acceptance Test Plan |

|

BOB |

Broker for Observation Blocks |

|

CCD |

Charge Coupled Device |

|

CCS |

Central Control Software |

|

CPU |

Central Processing Unit |

|

DCS |

Detector Control Software |

|

DFE |

Detector Front-End Electronics |

|

DICB |

ESO Data Interface Control Board |

|

DMA |

Direct Memory Access |

|

DRS |

Data Reduction Software |

|

DSP |

Digital Signal Processor |

|

FDR |

Final Design Review |

|

FITS |

Flexible Image Transport Format |

|

FWHM |

Full Width Half Maximum |

|

GUI |

Graphical User Interface |

|

HW |

Hardware |

|

HOS |

High Level Operating Software |

|

ICS |

Instrument Control Software |

|

IEE |

Institution of Electrical Engineers ( |

|

IEEE |

Institute of Electrical and Electronics Engineers ( |

|

INS |

Instrumentation Software |

|

I/O |

Input/output |

|

IR |

Infra-Red |

|

ISDD |

Instrument Software Design Description |

|

ISFS |

Instrument Software Functional Specification |

|

ISURS |

Instrument Software User Requirements Specification |

|

ISUMM |

Instrument Software User and Maintenance Manual |

|

IWS |

Instrument Workstation |

|

LAN |

Local Area Network |

|

LCC |

LCU Common Software |

|

LCU |

Local Control Unit |

|

MIDAS |

ESO-Munich Image Data Analysis System, ESO-MIDAS TM |

|

MS |

Maintenance Software |

|

MTBF |

Mean Time Between Failures |

|

MTBS |

Mean Time Between Service |

|

N/A������� |

Not Applicable |

|

|

Observation Block |

|

OBD |

Observation Block descriptor |

|

OLAS |

On-Line Archive Subsystem |

|

OLDB |

On-Line DataBase |

|

OMT |

Object Modeling Technique |

|

OO |

Object Oriented |

|

OS |

Observation Software |

|

|

Observer Support Software |

|

PAE |

Preliminary Acceptance |

|

PAF |

Parameters File |

|

PDR |

Preliminary Design Review |

|

QE |

Quantum Efficiency |

|

RAM |

Random Access Memory |

|

SNR |

Signal to Noise Ratio |

|

SOS |

Supervisory Observation Software |

|

STRAP |

System for Tip-tilt Removal with Avalanche Photodiodes |

|

SW |

Software |

|

TBC |

To Be Clarified |

|

TBD |

To Be Defined |

|

TCCD |

Technical CCD |

|

TCS |

Telescope Control Software |

|

TIM |

Time Interface Module |

|

TRS |

Time Reference System |

|

TSF |

Template Signature File |

|

UIF |

(Portable) User Interface (Toolkit) |

|

UNIX |

Trademark of Bell Laboratories (operating system) |

|

UV |

Ultra-Violet |

|

VCSOLAC |

VLT Control Software On-Line Archive Client |

|

VLT |

Very Large Telescope |

|

VME |

Versa Module Eurocard |

|

VOLAC |

VLT On-Line Archive Client |

|

WS |

Workstation |

|

|

|

The following is defined in [AD 02]:

� Exposure

� Integration

� Instrument Mode

� Instrument Workstation

The following is defined in [AD 07]:

� Observation Block

� Template

� Template Signature File

The following is defined in [AD 03]:

� Setup file

� Short Hierarchical Format

The following is defined in [AD 11]:

� User

The following is defined in [RD 07]:

� Assembly

The following styles are used:

bold

in the text, for commands, filenames, pre/suffixes as they have to be typed.

italic

in the text, for parts that have to be substituted with the real content before typing.

teletype

for examples.

<name>

in the examples, for parts that have to be substituted with the real content before typing.

bold and italic are also used to highlight words.

This implementation follows the naming conventions as outlined in [AD 03].

1.9 Problem Reporting/Change Request

The form described in [RD 05] shall be used.

The following graphical notation is

used in Chapter 3 (see [RD 06]):

|

Asynchronous message |

|

A form of

communication in which a producer task sends a message to a consumer task and

does not wait for a response; a message queue could potentially build up

between the tasks. Also referred to as �loosely coupled message

communication�. |

|||

|

Dependency |

|

Show which component and/or package communicates and/or depends

with/on another one. |

|||

|

Package |

|

A group of modelling elements. |

|||

|

Component |

|

An active

self-contained object with a well-defined interface. |

|||

|

Interface |

|

The external specification of a class, task or component. |

|||

|

Actor |

|

Shows an

outside user or related set of users who interact with the system. |

|||

|

Node |

|

In a

distributed environment, each node consist of one or more processors with

shared memory. |

|||

|

|

|

An instance

of a class that contains both hidden data and operations on that data. |

|||

|

|

|

A use case

realization is a graphic sequence of events, also referred to as a scenario

or an instance of a use case.� These

realizations or scenarios are depicted in either a sequence or collaboration

diagram. |

This document tries to associate, whenever

possible, every functional aspect to one of the standard instrumentation

modules (ICS, DCS, OS,

The present chapter aims to give an overview of the instrument hardware and software architecture.

Chapter 3 presents the results of the analysis of requirements in form of use cases presentation.

Chapter 4 describes the functionality of the ICS module

Chapter 5 describes the functionality of the DCS module

Chapter 6 describes the functionality of the OS module

Chapter 7 describes the functionality of the MS module

Chapter 8 describes the functionality of the

Chapter 9 describes the functionality related to the whole instrument

Chapter 10 describes aspects about the project organization

The instrument ID will be XXXX. The instrument prefix will be xx. [ISFS01]

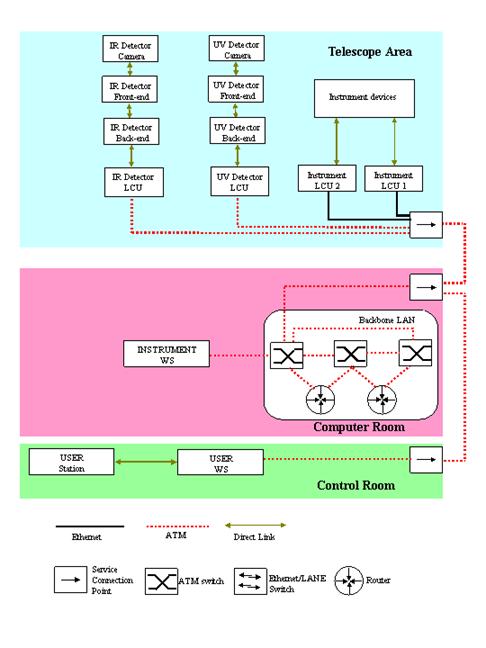

Figure 1 gives an overview of the instrument hardware architecture.

Following the VLT standard system architecture, the instrument hardware will be located in the Telescope Area.

As from [AD 06], the instrument devices will be controlled from two LCUs.

The two scientific detectors are controlled by two dedicated Detector LCUs (Ultra-Sparc Workstations).

Control and data information is transferred over the Instrument LAN between the Instrument Workstation and the Instrument and Detectors LCUs.

The Instrument

Workstation (IWS) is located in the Computer Room in the

Only the LCU controlling the image derotator

device will be equipped with a TIM board and connected to the Time

Reference System. The other LCUs have no time critical synchronization

requirements and will therefore not be equipped with a TIM board [ISFS02].

The two screens of the User Station console will be used: one for control and status display and the other one for real-time image display (see 9.3).

The Instrument LCUs have a normal Ethernet connection to the Instrument LAN.

The two scientific detectors LCUs, as well as the Instrument WS, have a large bandwidth ATM connection to the Instrument LAN.

The name of the nodes will be [ISFS03]:

- wxxxx for the Instrument Workstation

- lxxics1 for the first instrument LCU

- lxxics2 for the second instrument LCU

- wxxdir for the infra-red science detector LCU

- wxxduv for the ultra-violet science detector LCU

Figure 1 Hardware architecture

Figure 2 shows the architecture of the instrument software and the data flow between its components [ISFS80].

The instrumentation

software is subdivided in the standard

INS modules (see [AD 02]) ICS, DCS, OS,

MS,

Observation Blocks (OBs) are normally prepared by the observing team at the home institute well before the observing night, using the Phase 2 Proposal Preparation (P2PP) Tool.

During the

observing run, the next

BOB reads the

contents of the

The typical simple sequence of commands sent to OS by science observation templates to execute an exposure is:

- SETUP (one or more)

- START (exposure)

- WAIT (till exposure finished)

As a result of an exposure, the related DCS generates detector data and saves them in a FITS file. The OS process responsible for archiving data takes care of merging into that file the information, coming from the other sub-systems (TCS and ICS), related to the same exposure. It then informs the standard VLT On-Line Archive (VOLAC) process that a new file is ready to be archived. In turn, VOLAC passes this information to the standard VCSOLAC process, which finally transfers the file to the On-Line Archive Subsystem (OLAS) on the On-Line Archive WS.

The environments used by the instrumentation software are [ISFS06]:

- wxxxx on the Instrument Workstation. Type CCS-lite

- lxxics1 on the first instrument LCU

- lxxics2 on the second instrument LCU

- wxxduv on the UV science detector LCU. Type CCS-lite

The IR science detector

LCU Software runs under no-CCS and therefore does not need any CCS environment.

Two UNIX users will be dedicated to this instrument [ISFS07]:

- xxxxmgr, responsible for building and installing the Software

- xxxx, responsible for

starting/stopping and running the INS environments and the INS Software

Figure 2 Software architecture

This section is optional. If use cases are

included (recommended, limited to the most important or peculiar/complex ones),

they should follow the UML notation.

The following are just examples of use cases

in the UML notation. They are copied from the OmegaCAM functional specs and

therefore reflect the peculiarities of that instrument. They are not supposed

to be considered valid for all instruments and therefore should NOT be copied

without any adaptation to the actual instrument.

Describe here the contents of Figure 3

Figure 3 Scientific Operations Use Case

Figure 4 shows the sequence diagram for target acquisition. During

target acquisition the telescope is preset to the target and the auto-guiding

subsystem is prepared to perform auto-guiding during subsequent exposures. In

parallel with the telescope preset, the auto-guiding software queries the guide

star catalogue for candidate guide stars. After the telescope has preset, guide

stars are selected, possibly with operator intervention.

Figure 4 Acquire Target Use Case sequence diagram

Figure 5 shows the sequence diagram for instrument setup. Instrument setup is performed to prepare the instrument for an exposure.

The most important operation is the filter exchange. A filter dependent focus

offset (if any) is applied by asking the Telescope Control System to move M2.

In case the setup is for a calibration observation of type dome flat, than

lamps are switched on (not shown in the figure).

Figure 5 Setup Instrument Use Case sequence diagram

Figure 6 shows the sequence diagram for the execution of an

exposure. Before starting single exposures

with the science detector, OS checks that the telescope can track on target for

the required exposure time. Then ICS and telescope are instructed that an

exposure is going to start so that they can collect FITS header information.

DCS are then started: a command is sent to DCS-2 (slave) that instructs it to

start when it will receive a synchronization signal from DCS-1. When DCS-2 is

ready to get this signal a START command is sent to DCS-1, this effectively

starts the exposure on both DCSes. At exposure end header data information is

collected from ICS and TCS, and a merged data file is produced and sent to

archive.

Figure 6 Perform Exposure Use Case sequence diagram

Figure 7 shows the sequence diagram for the filter

substitution. Filter substitution is a maintenance

operation performed by means of a template. It begins with insertion in the

optical path of a filter from the magazine other then the one being serviced

(typically opaque or key filter). A SETUP command with filter ID (or name) and

position is issued for each filter to be inserted. The command is forwarded by

OS to ICS, that moves the magazine in order to put the filter in the requested

position to the loading plane, undocked. When the ICS status becomes

"waiting for filter ID", the operator removes the existing filter,

inserts the new one. ICS reads the filter ID, validates it, updates the

position/filter ID in the database and returns successfully.

Figure 7 Substitute Filters Use Case sequence diagram

4 INSTRUMENT CONTROL SOFTWARE (ICS)

One

single ICS controls all devices, except the detectors [ISFS16].

It consists of one part, which runs on LCU(s) and one part, which runs on the IWS.

The LCU part is responsible for the interface to the devices hardware and the low-level control. No real-time functionality is required.

The WS part is responsible for the coordination between LCUs and for the API to OS.

Both WS and LCU part will be based on the

VLT standard icb package [ISFS30].

The following tables describes the devices seen by the control electronics and related software, i.e. those devices that are to be controlled or sensors whose output is to be monitored.� See also [AD 06].

Table 1Total number of ICS devices

|

TYPE |

SYMBOL |

Total |

|

Lamps |

LAM |

4 |

|

Shutters |

SHU |

1 |

|

Servo driven rotational motion, no limit switches |

ROT |

6 |

|

Servo driven linear motion (slide), limit switches |

LIN |

2 |

|

Servo driven rotational motion, no limit switches, used

to generate a linear motion, requiring position lookup table |

EXC |

2 |

|

All types of sensors, simple or complex; PMT's,

temperature sensors, LN2 level detectors, vacuum sensors, contacts. Analogue

or logical values (in digital form). |

SEN |

2 |

|

|

|

17 |

|

# |

Device |

NAME |

TYPE |

FITS KEYS |

VALUES |

LCU |

REMARKS |

|

1 |

Calibration mirror slide |

CALS |

LIN icbMOT_MIRROR |

INS.MIRR1.NAME |

TELESCOPE SPHERE THAR1 THAR2 |

1 |

Slide with 4 positions |

|

2 |

ThAr� lamp 1 |

TAL1 |

LAM icbLAMP |

INS.LAMP1.ST |

T/F |

1 |

T=On F=Off Special power level in standby state [ISFS24] |

|

3 |

ThAr lamp 2 |

TAL2 |

LAM icbLAMP |

INS.LAMP2.ST |

T/F |

1 |

T=On F=Off Special power level in standby state [ISFS24] |

|

4 |

ThAr shutter |

TSH |

SHU icbSHUTTER |

INS.SHUT1.ST |

T/F |

1 |

T=Open F=Close |

|

5 |

FF lamp 1 |

FFL1 |

LAM icbLAMP |

INS.LAMP3.ST |

T/F |

1 |

T=On F=Off On sphere |

|

6 |

FF lamp 2 |

FFL2 |

LAM icbLAMP |

INS.LAMP4.ST |

T/F |

1 |

T=On F=Off On sphere |

|

7 |

Image derotator |

DROT |

ROT icbMOT_DROT |

INS.DROT.MODE INS.DROT.POSANG INS.DROT.RA INS.DROT.DEC |

SKY ELEV STAT [0.0 � 360.0] |

1 |

1) derotate sky (fixed position angle of slit on the

sky). Position angle selectable by observer. Default: N/S 2) derotate elevation direction (align the elongation

direction of the stellar image with the slit) to eliminate need for ADC 3) stationary, used with image slicer |

|

8 |

Preslit filter wheel |

PFIL |

ROT icbMOT_FILTER |

INS.FILT1.NAME |

B U � FREE |

1 |

Wheel with 16 positions |

|

9 |

Mode selector |

MODE |

LIN icbMOT_MIRROR |

INS.MIRR2.NAME |

IR UV DICHROIC |

1 |

Slide with 3 positions |

|

10 |

UV slit |

UVSS |

EXC icbMOT_SLIT2_WID |

INS.SLIT1.WID |

[0.01 � 10.00] |

2 |

Width in arcsec. Backlash |

|

11 |

UV filter wheel |

UVFIL |

ROT icbMOT_FILTER |

INS.FILT2.NAME |

B U � FREE |

2 |

Wheel with 24 positions |

|

12 |

UV cross disperser |

UVCD |

ROT icbMOT_GRATING2 |

INS.GRAT1.NAME INS.GRAT1.WLEN |

GRAT1 GRAT2 [9000 �11000] [8000 �10000] |

2 |

User specifies grating and order number [ISFS26]. Two

gratings back to back. |

|

13 |

IR slit |

IRSS |

EXC icbMOT_SLIT2_WID |

INS.SLIT2.WID |

[0.01 � 10.00] |

2 |

Width in arcsec. Backlash |

|

14 |

IR filter wheel |

IRFIL |

ROT icbMOT_FILTER |

INS.FILT3.NAME |

B U � FREE |

2 |

Wheel with 24 positions |

|

15 |

IR cross disperser |

IRCD |

ROT icbMOT_GRATING2 |

INS.GRAT2.NAME INS.GRAT2.WLEN |

GRAT3 GRAT4 FREE [12000-15000] [11000-14000] |

2 |

User specifies grating and order number [ISFS26]. Two gratings back to back. |

|

16 |

UV camera temperature monitoring |

TUVC |

SEN (CRY) xxiLAKE (special) |

INS.TEMP1.VAL |

|

2 |

Value in deg C Sampling period 60 sec [ISFS27] |

|

17 |

IR camera temperature monitoring |

TIRC |

SEN (CRY) xxiLAKE (special) |

INS.TEMP2.VAL |

|

2 |

Value in deg C Sampling period 60 sec [ISFS27] |

For every special device, a justification

why none of the icb standard devices can be used must be given.

The

only special devices are the two camera temperature monitoring sensors (TUVC

and TIRC). None of the temperature sensor standard devices supported by icb fulfills the requirements in terms

of accuracy and operability in a cryogenic environment. For these reasons, a Lakeshore xyz device, not supported by icb, has been chosen [ISFS29].

For every device in a cryogenic environment,

a justification why it cannot be located outside shall be given (if already

done in another document, it is enough to refer to it).

The

only devices in a cryogenic environment (CRY) are the two camera temperature monitoring sensors (TUVC and TIRC).

They cannot be located outside the

cryogenic environments because they must be closely connected to the science

camera [ISFS28]

Due to mechanical backlash, the target position for the two slit devices (UVSS and IRSS) shall always be approached in the direction of increasing encoder steps. This will be achieved by using the two-steps motion feature provided by the standard VLT motor library [ISFS25]. The size of last step will be 100 encoder steps.

Actions on all devices (initialization,

setup) will be done in parallel, as they are fully independent from each

other [ISFS61]. This

functionality is embedded in the icb

architecture.

All calibration lamps are mutually exclusive, i.e. it does not make sense to have more than one turned on at one time.

In order to make the ICS API easier to higher level Software (OS), an assembly (see [RD 07]) will be implemented:

- INS.LAMP [ISFS45]. Possible values:

- OFF. All lamps are off. Shutter TSH is closed

- TAL1. Only Thar 1 is on. . Shutter TSH is open

- TAL2. Only Thar 2 is on. Shutter TSH is open

- FFL1. Only flat-field 1 is on. Shutter TSH is closed

- FFL2. Only flat-field 2 is on. Shutter

TSH is closed

The standard instrument states and related

commands to change state are described in [AD 03]. All scenarios have to fit into that scheme, because

the whole common Software relies on it.

The instrument states are the standard ones specified in [AD 03], namely:

- OFF [ISFS31]: part of the Software is not running and part of the LCUs and devices can be powered off.

- LOADED [ISFS32]: the whole hardware is powered on, the whole Software is running, but the interfaces to the hardware are not initialized.

- STANDBY [ISFS33]: the interfaces are initialized, but the hardware may not.

- Sphere lamps are off. ThAr lamps are in a special standby power status.

- Shutters are closed

- Encoders are on

- Motors current is off.

- Sensors monitoring is active.

- ONLINE

[ISFS34]: all software and hardware is loaded,

initialized and active. This is the normal state during operations.

Being

ICS based on the icb package, the

commands are those defined in the CDT

table for the process ic0Control [ISFS35].

All Setup keywords will be registered in the dictionary XXXX_ICS.

The following functionality is embedded in icb, and will be also implemented in the instrument specific code (e.g. special device LCU code), whenever applicable:

- The

syntax of Setup keywords shall

be checked for validity [ISFS41]

- The

value of Setup keywords shall be checked for validity before taking any

action [ISFS40]

- The

value of Setup parameters shall be stored in the LCU and/or WS on-line

database in dedicated attributes, different from the attribute

containing the corresponding status parameter [ISFS66].

- The

value of Setup parameters in the on-line database shall not be changed until a new SETUP command is executed [ISFS38].

All Status keywords will be registered in the dictionary XXXX_ICS

The following functionality is embedded in icb, and will be also implemented in the instrument specific code (e.g. special device LCU code), whenever applicable:

- The

syntax of Status keywords shall

be checked for validity against the dictionary and against the rules

defined in [AD 10] [ISFS41]

- Status

parameters shall be stored in the LCU and/or WS on-line database in

dedicated attributes, different from the attribute containing the

corresponding setup parameter [ISFS66].

- The

status of any on-going action, as well as its completion status, shall be

available in the on-line database [ISFS39].

- The

copying of status parameters from the LCU to the WS on-line database will

use the CCS scan system. Attributes will generally be updated on

change. Polling mode will not be used. [ISFS42]

All Configuration keywords, if not already registered in ICB_CFG, will be registered in the dictionary XXXX_CFG.

Configuration parameters will be stored in

dedicated files, belonging to module xxmcfg

(see 7.1) [ISFS37].

The following functionality is embedded in icb, and will be also implemented in the instrument specific code, whenever applicable:

- The

syntax of Configuration keywords shall be checked for validity against the

dictionaries [ISFS41]

- The

standard tool ctoo is used to

access these parameters from the ICS WS part and to make them available in

the LCU OLDB after booting [ISFS64].

The

following functionality is embedded in icb:

- The ICS part of the FITS header can be

obtained by issuing the standard command

STATUS �header [-dumpFits <filename>]

- It

shall contain the actual status of the instrument and all related devices

(also in simulation). It shall also contain: [ISFS50]

1. Camera temperature at start and end of exposure, mean value and standard deviation.

ICS shall provide an engineering GUI, based

on the VLT standard package icbpan [ISFS48].

Figure 8 shows a mockup of such GUI (example taken from Omegacam)

Figure 8 Mockup of ICS stand-alone engineering GUI

In addition to the standard logging embedded in the icb module, the code for the special devices shall provide the following logs [ISFS49]:

- Errors during the execution of any

command, according to the CCS error system rules.

- Temperature values, when they change by 0.1 Celsius degrees when the instrument is in operation or stand-by mode.

Power-up/down of the instrument will be made manually.

Power-up following a power failure may leave the instrument in a hazardous condition. Hardware interlocks will prevent aggravation of the condition e.g. by preventing movement of functions if temperature is too high. [ISFS78].

Software alarms will be implemented to warn the user that the environmental

conditions (e.g. temperature) are approaching the hardware limits (see 4.10.3)

They

shall be treated as low priority alarms. See 4.10.3.

The following alarms are foreseen [ISFS36]:

- UV

camera temperature too high

- IR

camera temperature too high

Monitoring of alarm conditions shall be active also when the instrument is in the STANDBY state (e.g. during daytime) [ISFS52].

All alarms will be logged as operational logs [ISFS53]

The Control Software shall support degraded operations in case of problems with devices hardware. In such cases, the behavior of the device hardware shall be simulated by software in the most realistic way as possible and at the lowest level as possible. Furthermore, it shall be possible for test and maintenance purposes to run ICS also where the LCUs are not available.

Two levels of simulation are implemented in icb:

- Simulation for the entire instrument LCU at workstation level.

- Simulation for device hardware at LCU level.

The

same levels of simulation will be

implemented also in the code for the special devices, thus giving the possibility

to run and test templates and OBs also at locations where the hardware or the

LCUs are not available [ISFS46].

The ICS GUI and

the ICS part of the FITS header shall clearly indicate which device is in hw

simulation [ISFS47].

All critical performance requirements must

be analyzed here. In particular, it shall be investigated if the usage of

standards fulfills all performance requirements or special solutions must be

considered instead. Information about performance aspects related to the usage

of the VLT common software is available in the VLT software documentation (User

Manuals) or may be provided by ESO software staff. Whenever uncertainties are

present, dedicated prototyping is mandatory and the results must be presented

here, together with the conclusions and the proposed solutions.

The following sub-sections are just examples

of typical fields where performance requirements are specified. They should not

be considered exhaustive for all instruments nor are all of them necessarily applicable

to all instruments.

It is required that the initialization of the whole instrument does not exceed xx sec. Because all devices will be initialized in parallel (see 4.1.4), the overall initialization time for the whole instrument shall correspond to that device, which takes longer. The devices which require higher accuracy and will take longer time to initialize are the cross-dispersers. It is expected that their initialization will be within the required maximum time. However, a final test will be possible only once a prototype of the device will be available [ISFS14].

It

is required that the setup of the whole instrument does not exceed xx sec. Because all devices will be

moved in parallel (see 4.1.4), the overall setup time for the whole instrument

shall correspond to that device, which takes longer. The devices which require

higher accuracy and will take longer time to move are the cross-dispersers. It is expected that their maximum setup time will be within the required limit. However, a

final test will be possible only once a prototype of the device will be

available [ISFS15].

The ICS Test Software shall consist of [ISFS44]:

- Low-level LCU test procedure for the Lakeshore special device (see [RD 04])

- High-level WS test procedure for the Lakeshore special device (see [RD 04])

- Self-test procedure, based on inscSelfTest (see [RD 04])

ICS will be based on icb and icbpan.

The cmm modules belonging to ICS are [ISFS43]:

- xxi. It is the main module and includes the ICS WS front-end and LCU simulator.

- xxipan. It includes the ICS stand-alone GUI

- xxilak. It includes the code

for the Lakeshore special device

5 DETECTOR CONTROL SOFTWARE (DCS)

The

instrument is equipped with two science

detector cameras [ISFS18].

Two DCSs will be in place, each

controlling one of the two science cameras [ISFS19].

The

DCS for the UV camera will be an instance of the standard FIERA package [ISFS20].

The

UV CCD detector size will be 2028 x 2048 pixels,

upgradeable to 4096 x 4096 [ISFS21].

The

DCS for the IR camera will be an instance of the standard IRACE package [ISFS107].

The

IR detector size will be 1024 x 1024 pixels [ISFS22].

The following read-out modes are foreseen [ISFS76]:

- UV CCD:

1.

two outputs, 125

kHz clock rate, no binning, max. one window

2.

one output, 250

kHz clock rate, binning 2x2, no window

3. ��

- IR detector:

1.

one output, 500

kHz clock rate, max. one window

2.

�..

Considering the chip size, the fastest acquisition will therefore be xx sec for the UV camera and yy sec for the IR camera.

The files, defining the clock patterns for each read-out mode, will be stored in dedicated cmm modules (see 5.14).

No

real-time or in general �fast� data processing (such that it must be performed

on the DCS LCU) is requested.

Standard

applications will be used for image display: rtd for the UV camera and irtd

for the IR camera. They implement all features required [ISFS65].

The DCS states are those defined by the

FIERA package (see [RD 09]) for the UV camera and by the IRACE package (see [RD 15]) for the IR camera. [ISFS20]

The

DCS commands are those defined in the FIERA fcdconCI.cdt

CDT file (see [RD 09]) for the UV camera and IRACE iracqServer.cdt CDT file (see [RD 15]) for the IR camera. [ISFS20]

The DCS setup keywords are those defined in the dictionary FCDDCS (see [RD 09]) for the UV camera and in the dictionary IRACE (see [RD 15]) for the IR camera. [ISFS20]

The

DCS status keywords are those defined in the dictionary FCDDCS (see [RD 09]) for the UV camera and in the dictionary IRACE (see [RD 15]) for the IR camera. [ISFS20]

The copying of status parameters from the UV

camera LCU to the WS on-line database will use the CCS scan system, configured

through the FIERA scripts fcdDcsScan.sh

and fcdosScan.sh [ISFS20]

Being

the IR camera software based on IRACE, its LCU part runs under no-CCS (no CCS

environment, no CCS on-line database).

The DCS configuration for each camera is stored in dedicated cmm modules (see 5.14) and consists of:

- One file containing configuration parameter values

- Clock pattern files and directories

The DCS configuration for the UV camera is installed using the standard FIERA script fcdInstall.sh.

The

DCS configuration for the IR camera is installed using the standard IRACE

script iracqInstallData.

The

DCS keywords for the FITS header are those defined in the dictionary FCDDCS (see [RD 09]) for the UV camera and in the dictionary IRACE (see [RD 15]) for the IR camera. [ISFS20]

The

DCS stand-alone engineering GUI will be that provided by the FIERA package (see

[RD 09]) for the UV camera and by the IRACE package (see [RD 15]) for the IR camera. [ISFS20]

The

DCS logs are those produced by FIERA package (see [RD 09]) for the UV camera and by the IRACE package (see [RD 15]) for the IR camera. [ISFS20]

The

Failure Mode Operations supported by FIERA are described in [RD 09], those supported by IRACE are described in [RD 15]. [ISFS20]

The

DCS simulation levels are those defined by FIERA (see [RD 09]) for the UV camera and by IRACE (see [RD 15]) for the IR camera. [ISFS20]

All critical performance requirements must

be analyzed here. In particular, it shall be investigated if the usage of

standards fulfills all performance requirements or special solutions must be

considered instead. Information about performance aspects related to the usage

of the VLT common software is available in the VLT software documentation (User

Manuals) or may be provided by ESO software staff. Whenever uncertainties are

present, dedicated prototyping is mandatory and the results must be presented

here, together with the conclusions and the proposed solutions.

The following sub-sections are just examples

of typical fields where performance requirements are specified. They should not

be considered exhaustive for all instruments nor are all of them necessarily

applicable to all instruments.

It

is required that the fastest acquisition for a 4096x4096 detector does not

exceed xx sec with a maximum overhead for the image transfer to the IWS of xx

sec. This corresponds to yy Mbit/sec

data rate. Such a rate can be sustained

by the standard ATM network connection between detector LCU and Instrument

Workstation and by the hard disk model and related interface mounted on VLT

standard IWS [ISFS12].

It is required that the maximum delay between end of image acquisition and end of image display does not exceed xx sec

Using

the Template Instrument as test bench and the VLT standard real-time display

tool, we have determined a maximum delay

over 20 acquisitions of yy sec. This shows that the VLT standard packages

(FIERA and IRACE for DCS and rtd for

the Real Time Display) are good enough for our requirements [ISFS13].

The DCS Test Software shall consist of [ISFS84]:

- Self-test procedure for the UV camera, consisting of taking one exposure for each read-out mode (see [RD 04])

- Self-test procedure for the IR camera,

consisting of taking one exposure for each read-out mode (see [RD 04])

DCS

for the UV camera is based on the FIERA

package [ISFS20]

DCS

for the IR camera is based on the IRACE

package [ISFS107].

Image

display is based on the rtd package [ISFS65]

The cmm modules belonging to DCS are [ISFS81]:

- xxdir. It includes the configuration files for the IR camera.

- fcdXXXXUV. It includes the configuration files for the UV camera. It is delivered by ESO.

The Observation Software (OS) is the highest layer of the control Software and will run in the Instrument Workstation (see Figure 2). It consists of:

- OS Server process, responsible for the execution of single exposures.

- OS Archiver process, responsible for archiving the results of exposures in FITS files.

- If

applicable, any process dedicated to special features, such as secondary

guiding

- If

applicable, Supervisory OS

- Templates, defining and running sequence of exposures

The OS processes (Server and Archiver) will

be based on the standard package boss

[ISFS75].

Templates will be based on the standard

package tpl [ISFS71].

The following instrument modes (keyword INS.MODE) are foreseen [ISFS74]:

- UVSPEC

(UV spectroscopy)

Whenever this mode is selected, the following setting must be automatically applied:

INS.MIRR2.NAME

UV

- IRSPEC

(IR spectroscopy)

Whenever this mode is selected, the following setting must be automatically applied:

INS.MIRR2.NAME

IR

- DSPEC

(Dichroic spectroscopy)

Whenever this mode is selected, the following setting must be automatically applied:

INS.MIRR2.NAME

DICHROIC

- IRIMG

(IR Imaging)

Whenever this mode is selected, the following setting must be automatically applied:

INS.MIRR2.NAME IR INS.GRAT2.NAME FREE

The

following sub-set of the standard exposure types (keyword DPR TYPE), defined in

[AD 10], will be used [ISFS85]:

- OBJECT

- SKY

- STD

- FLUX

- SPECTEMPL

- BIAS

- DARK

- FLAT

- LAMP

- WAVE

- FMTCHK

- ORDERDEF

In case of one SOS coordinating several

Describe here what you intend to implement,

in addition to what already provided by boss, and explain why.

Describe here what you intend to implement,

in addition to what already provided by boss, and explain why.

Describe here the processes you intend to

implement in addition to the Server and Archiver. Justify why the functionality

has to be implemented in separate processes and describe the interface to the

Server and other sub-systems.

The instrument states are the standard ones specified in [AD 03] and [RD 10], and described in section 4.3 [ISFS75].

The

OS commands are those defined in the boss

CDT file osbControl.cdt (see [RD 10]). [ISFS75]

The OS setup keywords are those defined in the dictionary XXXX_OS [ISFS82]

The OS status keywords are those defined in

the dictionary XXXX_OS [ISFS82]

All Configuration keywords are registered in the dictionary OSB.

Configuration parameters will be stored in

dedicated files, belonging to module xxmcfg

(see 7.1) [ISFS83].

The following functionality is embedded in boss, and will be also implemented in the OS specific code, whenever applicable:

- The

syntax of Configuration keywords will be checked for validity against the

dictionary [ISFS75]

The OCS keywords for the FITS header are

those defined in the dictionary XXXX_OS [ISFS82]

The following TCS standard functionality (see [RD 03]) will be used:

- Preset

- Offset

- Auto-guiding

- Adapter and rotator angle

Presetting will result in positioning the object in the defined instrument aperture and auto-guiding, using an off-axis guide star.

The whole functionality will be accessed from templates, in particular using methods of the standard tpl class tplTCS (see [RD 08]). [ISFS86]

The OS panels will be:

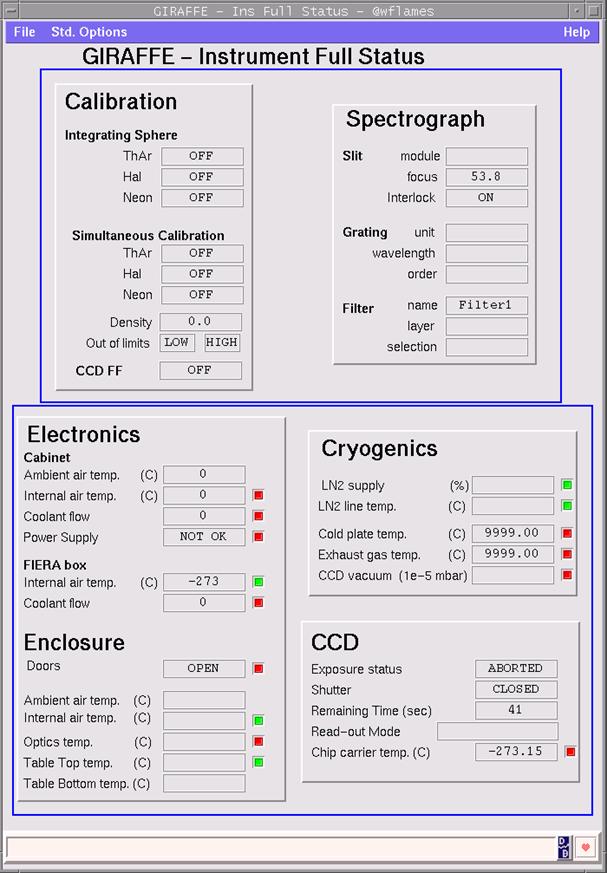

- OS Control GUI. A mockup is shown in Figure 9 (example taken from FLAMES)[ISFS87]

- OS

Status GUI. A mockup is shown in Figure

10 (example

taken from GIRAFFE)[ISFS88]

- If

applicable, panels dedicated to special functionality, e.g. slit viewer

control.

The

OS logs are those produced by the boss

package (see [RD 10]) [ISFS75]

Calibration and Observation data shall be stored in FITS files, according to the rules and guidelines defined in [AD 10].

The following functionality is embedded in boss and tpl, and will be also implemented in the OS specific code, whenever applicable:

- FITS files will follow the naming conventions described in [RD 08]. [ISFS59].

- The OS Server process shall inform the

OS Archiver process that it can start the archiving operations as soon as

it has completed collecting information for the FITS header from the

various sub-systems (ICS, TCS) after DCS has declared the exposure

complete from its side. This way archiving

and preparation of the next exposure can run in parallel [ISFS60].

Figure 9 Mockup of OS Control GUI

Figure 10 Mockup of OS Status GUI

The

implementation of templates will be

based on the rules defined in [RD 08] and on the standard tool tpl [ISFS71].

The parameter values used within OS

templates will always be in user units and never in engineering units (e.g.

encoder units) [ISFS89]

The

following templates are foreseen [ISFS72]:

�

Acquisition

1. XXXX_UVSPEC_acq. UV Spectroscopy standard object acquisition

Parameters:

� Instrument mode

� Object Coordinates

� �..

Sequence:

a. Set instrument mode

b. Preset telescope

c. Wait of auto-guiding and active optics active

d.

��

2.

�.

�

Calibration

- XXXX_UVSPEC_cal_std. UV Spectroscopy standard calibration. The first operation will be a SETUP command to turn on the calibration lamp selected (to optimize exposure cycle due to lamp warm-up time) [ISFS69]

Parameters:

� Instrument mode

� Lamp name

� Integration time

� �..

Sequence:

a. Set instrument mode

b. Switch lamp on

c. Wait for lamp to warm-up

d. Take a full frame exposure (integration time xx sec)

- �.

�

Science

- XXXX_UVSPEC_obs_std. UV Spectroscopy standard observation. Before starting the exposure, the derotator continuous motion must be started, with SETUP �function INS.DROT.MODE SKY [ISFS70]

Parameters:

� Instrument mode

� Integration time

�

�..

Sequence:

a. Set instrument mode

b. Setup the instrument according to the given parameters value

c. Take a full frame exposure (integration time specified by the user)

- �.

The setup reference files, used by all templates generating images, will always contain the keywords

DET.DISPLAY 0

DET.FRAM.FITSMTD 2

They

specify that images must be displayed

and saved in a FITS file [ISFS67].

OS

shall provide to P2PP, as part of the xxotsf

module, the Instrument Package XXXX.zip,

consisting of all the OS templates and the

Instrument Summary File XXXX.isf.

All critical performance requirements must

be analyzed here. In particular, it shall be investigated if the usage of

standards fulfills all performance requirements or special solutions must be

considered instead. Information about performance aspects related to the usage

of the VLT common software is available in the VLT software documentation (User

Manuals) or may be provided by ESO software staff. Whenever uncertainties are

present, dedicated prototyping is mandatory and the results must be presented

here, together with the conclusions and the proposed solutions.

The following sub-sections are just examples

of typical fields where performance requirements are specified. They should not

be considered exhaustive for all instruments nor are all of them necessarily

applicable to all instruments.

It is required that the execution of a bias full frame, from the start till when the complete FITS file is available on the IWS for being archived, shall not exceed xx sec (see [AD 11]).

Using

the Template Instrument as test bench, we have determined a maximum execution time over 20 exposures

with the FIERA DCS of yy sec and with the IRACE DCS of zz sec. This shows

that the VLT standard packages (FIERA and IRACE for DCS and boss for OS) are

good enough for our requirements [ISFS11].

The OS Test Software shall consist of [ISFS92]:

- OS processes test. Execute a sequence of typical exposures (see [RD 04]).

- OS templates test. Execute a self-test OBD consisting of the whole list of implemented templates (see [RD 04]).