Optical Fibres

Using Fibres to link Telescopes to Spectrographs.

Advantages

-

Spectrograph independent from telescope. Bench Spectrographs,

no weight

or volume restrictions.

-

High spectral stability.

-

Fibres are easy to use and install (once prepared!)

-

Possibility to perform two-dimension spectroscopy with fibre

bundles.

Drawbacks

-

Transmission losses.

-

Focal Ratio Degradation.

-

Circular aperture losses.

-

Poor sky subtraction.

-

Fixed “slit aperture”.

-

Difficult to prepare if not proper tools are available.

-

Fragile!

Fibre Transmission

|

These plots show the total transmission of

two types of commercial step index silica fibres for a length of 10 meters

(wet and dry). In for a length of 26 meters. These figures include the

Fresnel reflection losses at the ends of the fibre (~ 4% per glass surface). |

|

Same as previous but for a length of 26 meters. |

Focal Ratio Degradation (FRD)

|

This Figure shows the flux variation measured

in laboratory against the output aperture for different input beams (F/3,

F/6 and F/8). If an F/8 beam is launched into the fibre, only 55% of the

flux will be recovered at the output of the fibre and at the same aperture.

However for an input beam opened to F/3, 85% of the light will be recovered

by an output cone also opened to F/3. This focal ratio degradation increases

rapidly when the fibre is submitted to mechanical stresses like strong

bending and twists. |

|

This is the FRD for a fibre of 200 microns

core diameter. The total output flux has been normalized to 100% |

|

The Figure shows the FRD (same fibre) when

the fibre is submitted to a pretty strong bending. For an F/8 input beam,

only 44 % will be recovered at the same output aperture. However, for an

F/3 input beam, the degradation for a cone also opened to F/3, will be

only of few percent less that for the free fibre. From these experimental

values, we conclude that a telescope beam channeled by a fibre degrades

faster for slower beams (a slow beam has a high F/#, the opposite is a

faster beam). |

Working with fibres

|

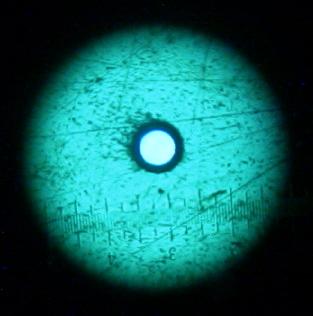

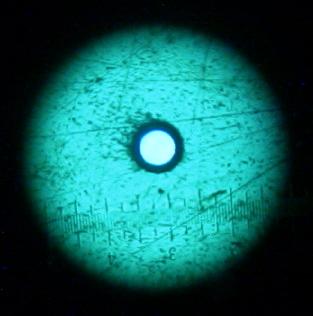

A microscopic view of metallic standard connector

with a 150microns fibre at the center. |

Flux Calculator

Here

there is an applet to calculate the flux passing through a slit versus a pinhole

Coupling to telescope

Here

there are some ways to connect the telescope to the optical fibre adapters

And, our first implementation of a mono-fibre head:.

|

Polymicro "wet" fibre of 200 microns core diameter

and its adapter to the telescope (1¼") |

|

Detail of the Fibre Head. The fibre input end is placed

just below the hole of the "mirror-diaphragm" (nickel plate, 0.1 mm

thickness and 10 mm diameter) |

And our latest implementation of a multi-fibre head

This is our original vision (modelled

in 3D and courtesy of Eduardo Ortíz Ostalé) of the above multi-fibre

head.